Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

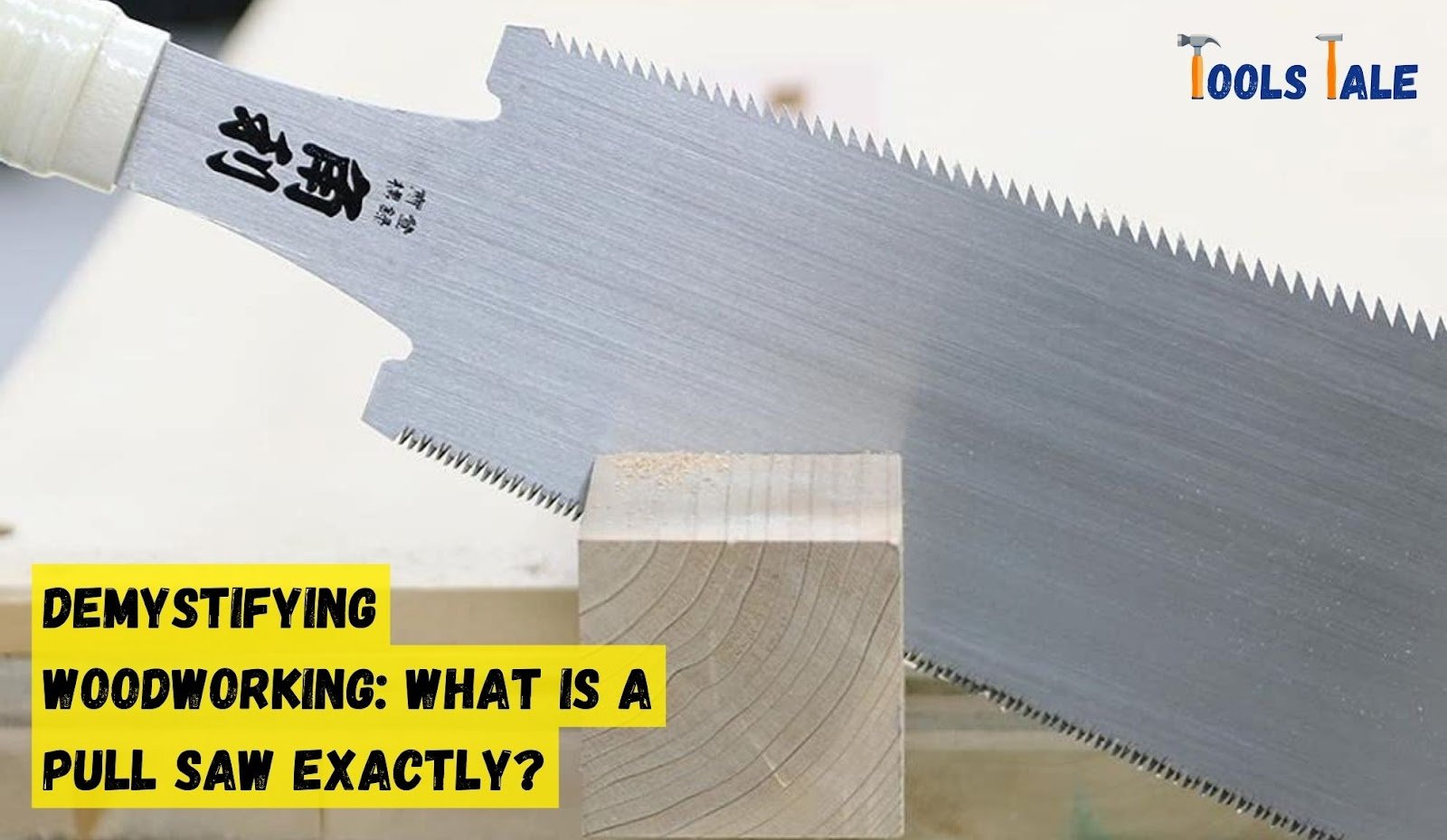

What is a pull saw? If you’re into woodworking, this nifty tool might just become your best friend in the workshop. But before we dive into the sawdust, let’s unravel the mystery together. Picture a saw that cuts on the pull stroke, making your woodworking projects a breeze. It’s all about precision, clean cuts, and versatility.

So, if you’re curious about this woodworking wizardry, stick around, because we’re about to explore the ins and outs of pull saws, revealing why they’re a must-have for any serious woodworker.

Key Summary: What is a Pull Saw?

A pull saw is a woodworking tool that cuts on the pull stroke, offering precision and control. Its thin blade with fine teeth makes it ideal for detailed work in tight spaces, favored by carpenters and DIYers. Easy to use, it’s a must-have for woodworking projects.

In the world of woodworking, precision is often the name of the game. Whether you’re crafting intricate joinery or shaping delicate details, the tools you choose can make all the difference. Enter the pull saw, a remarkable tool that many woodworkers swear by.

But what exactly is a pull saw, and how does it work its magic to create those flawless, precise cuts? In this article, we’ll explore the ins and outs of this unique tool, taking a deep dive into its anatomy, operation, and the art of creating precision cuts.

When it comes to woodworking, precision is the name of the game. Whether you’re crafting intricate joinery or shaping delicate details, the tools you choose can make all the difference. Enter the pull saw, a remarkable tool that many woodworkers swear by.

But what exactly is a pull saw, and how does it work its magic to create those flawless, precise cuts? In this article, we’ll explore the ins and outs of this unique tool, taking a deep dive into its anatomy, operation, and the art of creating precision cuts.

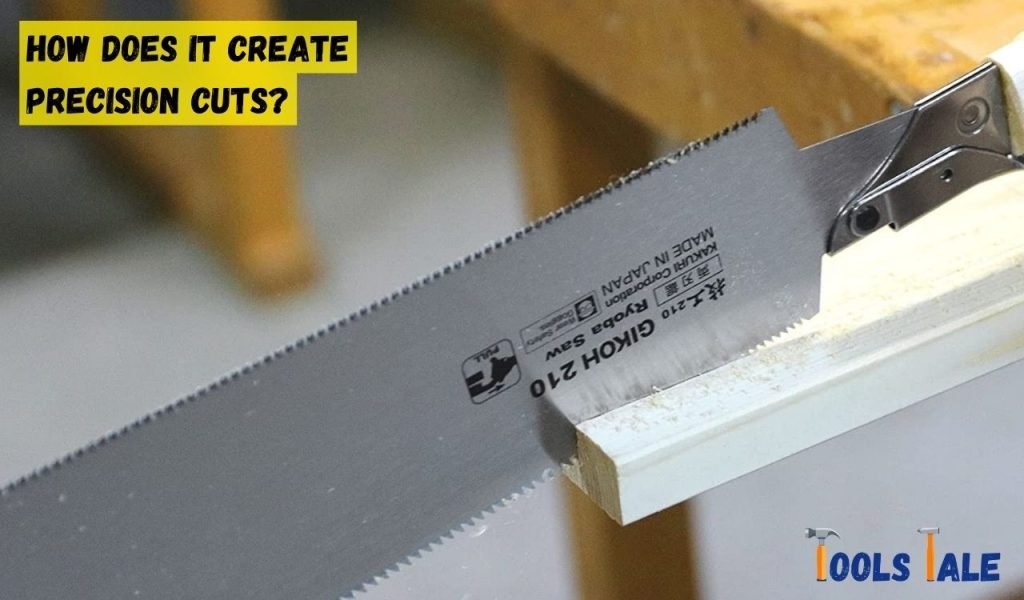

Imagine you’re in your workshop, working on a project that demands not just accuracy but a surgeon’s precision. You’ve got your pull saw in hand, and it’s time to make that crucial cut. But how does it manage to create those flawless, precise cuts every time? It all boils down to the pull saw’s unique design and operation.

Before we delve into the mechanics, let’s dissect a pull saw’s anatomy. To understand how it creates precision cuts, we need to know its key components.

At the heart of a pull saw is its blade. What sets it apart is the arrangement of its teeth. Unlike regular push saws, which cut primarily on the push stroke, pull saws feature teeth designed to cut when you pull the saw toward yourself. This design minimizes blade bending, resulting in cleaner, more accurate cuts.

A pull saw’s handle is ergonomically crafted to facilitate the pulling motion. It ensures a comfortable grip, allowing woodworkers to exert control without straining their wrists or hands. This ergonomic approach contributes to the precision pull saws are known for.

Now, let’s see the pull saw in action. Picture this: you’re crafting a piece of joinery that demands surgical precision. You reach for your trusty pull saw, align it with your marked line, and gently start the pull stroke.

As the blade glides smoothly along the wood’s surface, you’ll notice several key factors at play:

One of the standout features of pull saws is that they require less force compared to push saws. The controlled and steady pull motion allows for a gentler approach to cutting. This reduced force minimizes the risk of overcutting or damaging the wood, ensuring that your project remains pristine.

Perhaps the most striking aspect of using a pull saw is its natural ability to maintain a straight line. Woodworkers often marvel at how effortlessly the saw follows its course, resulting in incredibly accurate cuts. This straight-line precision is a testament to the pull saw’s design and functionality.

Using a pull saw is a gratifying experience, especially when it comes to the clean and splinter-free finish it leaves behind. Thanks to its fine teeth and pull-stroke operation, the blade slices through the wood with finesse, leaving the edges smooth and ready for further refinement.

While precision cuts are the hallmark of pull saws, their versatility extends beyond this primary function. Woodworkers often turn to pull saws for a range of tasks, including:

Pull saws are ideal for flush cutting, allowing you to trim dowels, tenons, or protruding joinery components with utmost precision. The pull stroke minimizes the risk of damaging surrounding surfaces, making it perfect for these delicate tasks.

Creating intricate dovetail joints demands precision and control. Many woodworkers opt for pull saws in this scenario, as they enable the crafting of dovetails that fit together seamlessly.

Whether you’re working on intricate inlays, delicate moldings, or small-scale carvings, the pull saw’s ability to deliver precise cuts makes it an invaluable companion for fine detailing work.

Now that we’ve explored the mechanics of pull saws and how they create precision cuts, it’s time to delve into the practical aspects of where and when to use these remarkable tools. Understanding the right situations and applications for pull saws is essential to harnessing their full potential in your woodworking endeavors.

Now that we’ve explored the mechanics of pull saws and how they create precision cuts, it’s time to delve into the practical aspects of where and when to use these remarkable tools. Understanding the right situations and applications for pull saws is essential to harnessing their full potential in your woodworking endeavors.

Pull saws find their place in a wide range of woodworking projects. Their precision and ease of use make them suitable for various applications, including:

If your project involves delicate detailing, intricate inlays, or small-scale carvings, a pull saw is your ideal companion. Its ability to deliver precise cuts ensures that you can achieve intricate designs with ease.

Pull saws excel in joinery work, where accuracy is paramount. Crafting dovetail joints, tenons, and other precision joinery becomes more manageable and enjoyable with the clean cuts they provide.

Trimming dowels, tenons, or protruding joinery components requires finesse and control. Pull saws are perfect for flush cutting tasks, as they minimize the risk of damaging surrounding surfaces.

One of the advantages of pull saws is their compact size and portability. They are often favored by woodworkers who need a versatile cutting tool that can be easily carried to different job sites or workshops.

Pull saws shine in situations where traditional saws struggle to reach. Their thin, flexible blades can navigate tight spots, making them indispensable for tasks in confined or challenging spaces.

Now that you know when and where to use pull saws, let’s explore some valuable tips and techniques to ensure your cutting experiences are as smooth and effortless as possible.

Sharpness is key to a pull saw’s performance. Regularly sharpen your saw’s blade to maintain its cutting precision. A sharp blade reduces the effort required for cutting and ensures cleaner results.

When using a pull saw, avoid applying excessive force. Let the saw’s design and sharp teeth do the cutting for you. Exerting too much pressure can lead to overcutting or blade damage.

Accurate cutting begins with precise marking. Always mark your cut lines before using a pull saw. This ensures that you stay on track and achieve the desired results.

To prevent slipping or movement during cutting, secure your workpiece firmly in place. This ensures stability and safety while using the pull saw.

Maintain a steady and controlled pulling motion while using the saw. Avoid abrupt movements or jerking, as these can lead to uneven cuts. Consistency in your strokes results in cleaner and more accurate cuts.

Check and adjust the tension of your pull saw’s blade regularly. Proper tension ensures that the blade remains straight and rigid during cutting, contributing to precise results.

Lastly, always prioritize safety when using any woodworking tool. Wear appropriate safety gear, such as safety goggles and gloves, to protect yourself from potential hazards.

Choosing the right pull saw is essential to ensure that you have a tool that suits your specific woodworking needs. With various types and features available, selecting the perfect pull saw can make a significant difference in the quality of your cuts and overall woodworking experience.

Pull saws come in different types, each tailored for specific tasks. The two most common types are:

Consider the type of woodworking projects you commonly undertake and choose a pull saw that aligns with your needs.

The blade length and teeth per inch (TPI) determine the saw’s cutting capacity and finish. Longer blades are suitable for larger workpieces, while shorter ones provide better control for intricate cuts. TPI indicates the fineness of the teeth; a higher TPI results in smoother cuts, while a lower TPI is better for aggressive cutting.

Ergonomics play a crucial role in user comfort and control. Test the saw’s handle to ensure it feels comfortable in your hand and allows for a secure grip. Some pull saws come with interchangeable handles, allowing you to customize the grip to your liking.

Invest in a reputable brand known for producing high-quality pull saws. While it may be tempting to opt for a budget-friendly option, a well-made pull saw will provide better performance, longevity, and precision.

Proper maintenance and care are essential to keep your pull saw in optimal condition and extend its lifespan. Regular upkeep ensures that it continues to deliver precise cuts and remains a reliable tool in your woodworking arsenal.

After each use, clean your pull saw to remove wood residue and prevent corrosion. Use a soft brush or compressed air to remove sawdust and debris from the blade and teeth. For stubborn residue, a solvent designed for saw blades can be used sparingly.

To protect the blade from rust and damage, consider using blade protectors or covers. These are often available from the same manufacturers who produce pull saws and are designed to fit your specific saw type.

Maintaining a sharp blade is crucial for precise cuts. Regularly inspect the blade for dullness and use a sharpening file or stone to restore its sharpness. Follow manufacturer recommendations for the appropriate angle and technique.

Over time, pull saw blades can wear out or become damaged. When you notice a decline in cutting performance or visible signs of wear, it’s time to replace the blade. Most pull saws allow for blade replacement, and replacement blades are readily available.

Store your pull saw in a dry, cool place to prevent moisture and rust. Hanging the saw or using a dedicated saw rack can help maintain blade integrity and prevent accidental damage.

If your pull saw has a wooden handle, periodically check for signs of wear, cracks, or loose fittings. Handle maintenance may include sanding, refinishing, or replacing the handle as needed.

In conclusion, What is a pull saw? It’s a woodworking tool that operates on the pull stroke, delivering precision and clean cuts. Whether you’re a seasoned woodworker or just starting out, the pull saw can be a game-changer in your craft.

With its versatility and ability to handle various tasks, it’s a valuable addition to any workshop. Now that you know the ins and outs of pull saws, it’s time to grab one and start creating with confidence.

A pull saw is also known as a pull stroke saw. This name refers to its cutting action, where you pull the saw toward yourself to make cuts.

It’s called a pull saw because of its unique cutting motion. Unlike traditional push saws, you exert force by pulling it, allowing for precise control.

Yes, pull saws are highly regarded in woodworking. They are known for their precision, clean cuts, and versatility, making them valuable tools for various tasks.

The primary purpose of a pull saw is to make precise cuts in woodworking. It’s commonly used for joinery, fine detailing, flush cutting, and tasks that require accuracy.

Pull saws are primarily designed for cutting wood. While some may cut soft metals, they are not suitable for heavy-duty metal cutting, as metalworking saws are better suited for that purpose.

A tree pull saw is designed for cutting branches and limbs. Hold it at an angle, apply light pressure, and use a pulling motion for efficient and controlled cutting.

Use a pull saw when you need precise and clean cuts in woodworking projects. It’s ideal for tasks like joinery, dovetailing, flush cutting, and fine detailing where accuracy is crucial.