Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

How does jack hammer work? Curious about the mighty force that breaks concrete like a breeze? Get ready to unveil the secrets behind this demolition hero! In just a few sentences, we’ll dive into the heart of a jackhammer’s operating principle and reveal how it wields its remarkable power.

From pounding precision to versatile applications, the jackhammer’s prowess knows no bounds. So, buckle up and prepare to be amazed by the sheer force and finesse of this construction marvel. Let’s embark on an exciting journey into the world of jackhammers and discover the magic behind their demolition dance!

Key Summary: How Does Jack Hammer Work?

Jackhammers, or pneumatic breakers, work by using compressed air to deliver rapid hammering motion. This powerful impact breaks concrete and rocks, making them essential tools in construction and demolition. Discover the engineering behind these impactful machines.

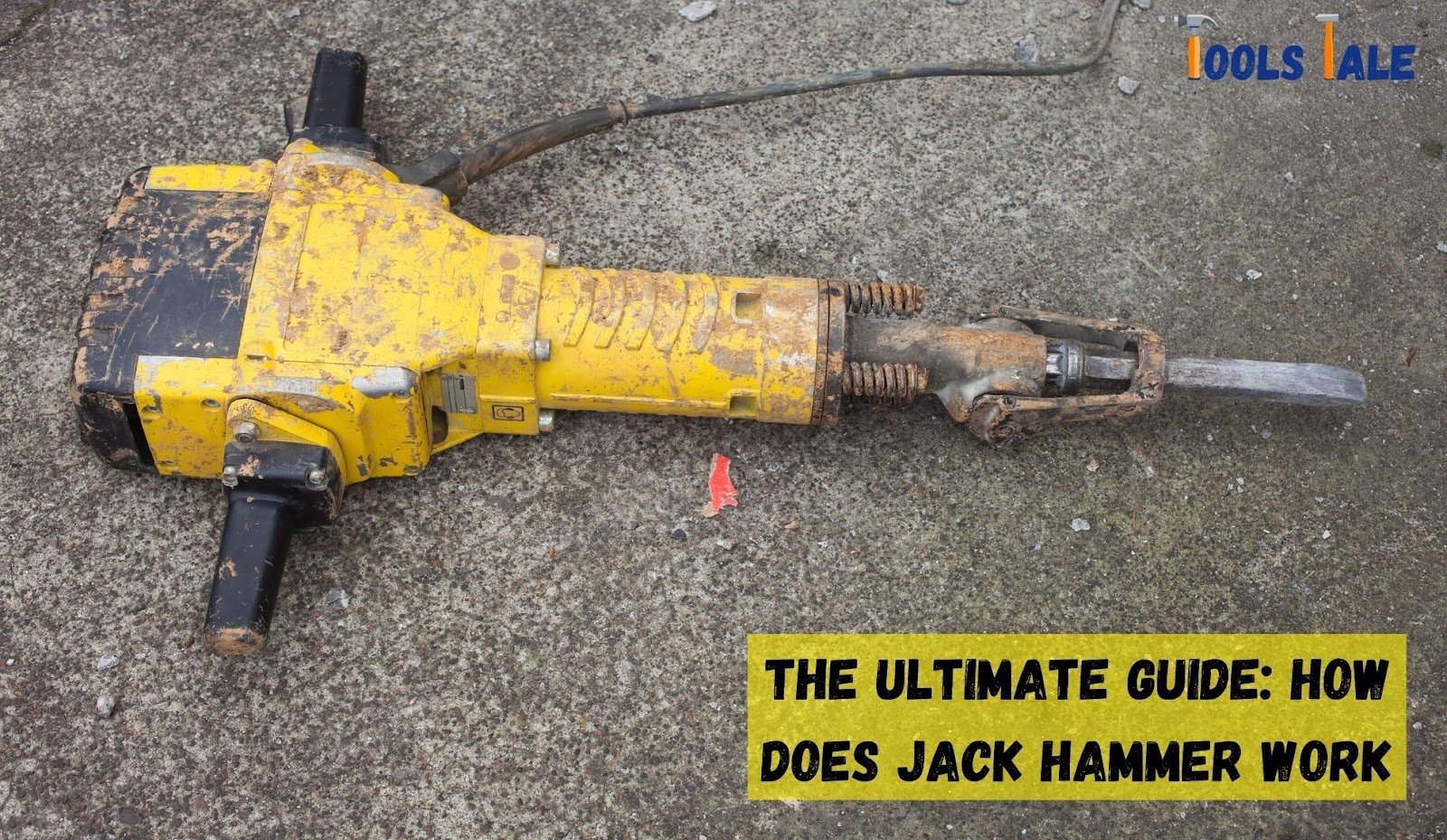

A jackhammer, also referred to as a pneumatic hammer or demolition hammer, is a robust and high-powered construction tool widely used in various industries for breaking through tough surfaces and demolishing structures.

The key feature that sets a jackhammer apart is its ability to deliver rapid and forceful blows, making it exceptionally efficient for tasks like breaking concrete, rocks, pavements, and other hard materials.

At its core, a jackhammer operates by converting external power, typically from sources like compressed air, electricity, or hydraulic systems, into powerful vertical movements. These movements are generated by a heavy metal cylinder known as the hammer or piston, which moves up and down at remarkable speed.

The striking force of the jackhammer is channeled through a drill bit attached to its front end. As the piston drives the drill bit against the surface, it generates intense impact, effectively fracturing and removing the targeted material.

The repetitive pounding motion allows for precise and controlled demolition, making the jackhammer an indispensable tool in construction, roadworks, demolition projects, and other heavy-duty applications.

With its remarkable power and versatility, the jackhammer has revolutionized the construction industry, saving time and labor while ensuring efficient and precise results in various demolition and excavation tasks.

Whether it’s renovating buildings, repairing roads, or clearing space for new construction, the jackhammer remains a vital tool for tackling tough and challenging projects.

To understand the magic of a jackhammer, let’s break down its operation into a step-by-step guide:

The jackhammer gets its energy from an external power source, commonly pneumatic, electric, or hydraulic. Pneumatic jackhammers utilize compressed air supplied through a hose from an air compressor, while electric jackhammers run on electricity, making them ideal for indoor projects. Hydraulic jackhammers, on the other hand, use hydraulic power, often harnessed from machinery like excavators.

At the core of every jackhammer is the hammer or piston, a heavy metal cylinder responsible for the powerful impacts. As the operator triggers the power source, the piston moves up and down at an incredible speed, generating forceful blows.

Mounted at the front end of the jackhammer is the drill bit, the tool’s business end. When the piston moves downward, it pushes the drill bit against the surface with immense pressure, breaking apart the material. The drill bit repeatedly strikes the surface in quick succession, efficiently fracturing and removing the targeted material.

Skilled operators know that proper handling is essential for using a jackhammer effectively. The operator maintains a firm grip on the handle, allowing the tool’s weight and mechanics to do the work. By controlling the jackhammer’s movement and positioning, the operator directs its power to the desired area.

Have you ever marveled at the sheer power of a jackhammer, as it breaks through concrete with ease, like a superhero wielding a mighty tool? Well, let’s lift the curtain and reveal the engineering brilliance behind this construction marvel.

At the heart of every jackhammer lies its operating principle – the generation of high-impact blows. Imagine a heavy metal cylinder, known as the hammer or piston, moving up and down at incredible speed. This powerful motion is powered by an external energy source, commonly pneumatic (compressed air), electric, or hydraulic.

Mounted at the front of the jackhammer is the drill bit – the tool’s business end. As the piston rapidly moves downward, it drives the drill bit into the surface with tremendous force. The drill bit strikes the material repeatedly in quick succession, efficiently fracturing and removing the targeted area.

Using a jackhammer may seem like a Herculean task, but skilled operators make it look effortless. The operator’s control is crucial in directing the jackhammer’s force to the precise spot, guiding the demolition dance with finesse.

While a jackhammer’s power is awe-inspiring, safety should always be the primary concern. Operating a jackhammer securely and confidently requires adherence to safety guidelines.

Have you ever witnessed the impressive force of a jackhammer, breaking through concrete like a powerful giant? Let’s embark on a journey to explore the fascinating world of jackhammers and their versatile applications in various industries.

At the core of a jackhammer’s operation lies its ability to deliver rapid, high-impact blows. Picture a heavy metal cylinder, known as the hammer or piston, moving up and down at remarkable speed. This powerful motion is fueled by an external energy source, such as compressed air, electricity, or hydraulic power.

Mounted at the front end of the jackhammer is the drill bit – the tool’s business end. As the piston moves downward, it drives the drill bit against the surface with incredible force. The repeated strikes from the drill bit effectively fracture and remove the targeted material, making quick work of even the toughest surfaces.

The versatility of jackhammers makes them indispensable in various industries:

To ensure your jackhammer remains a reliable companion for the long haul, proper maintenance is key.

The power of a jackhammer commands respect, making safety a top priority when using this tool.

While jackhammers are powerful allies on construction sites, prolonged and improper use can lead to health consequences.

Sustained and frequent use of jackhammers exposes operators to hand-arm vibration, which can lead to Hand-Arm Vibration Syndrome (HAVS). HAVS is a condition that affects the blood vessels, nerves, and muscles in the hands and arms.

Symptoms may include numbness, tingling, and reduced grip strength. To mitigate the risk of HAVS, operators should use well-maintained tools with low vibration levels and take regular breaks during extended use.

Operating a jackhammer produces intense noise levels that can lead to hearing loss over time. The continuous exposure to loud noise without proper hearing protection can cause irreversible damage to the auditory system. To protect hearing health, operators must wear appropriate hearing protection, such as earplugs or earmuffs, to reduce noise exposure.

The repetitive and forceful movements involved in jackhammer operation can strain the muscles and joints of the arms, shoulders, and back. Improper posture and technique can exacerbate musculoskeletal strain, leading to discomfort and injuries. Operators should be mindful of their body mechanics, use ergonomic handles, and take regular breaks to alleviate the strain on their musculoskeletal system.

In addition to hand-arm vibration, jackhammer operators may also experience whole-body vibration (WBV) transmitted through the feet and body. Prolonged exposure to WBV can lead to lower back pain and other musculoskeletal issues. Using anti-vibration gloves and wearing appropriate footwear with shock-absorbing properties can help reduce the impact of WBV.

Working in dusty environments, such as construction sites, can expose jackhammer operators to airborne particles and pollutants. Inhaling dust and other contaminants may cause respiratory problems over time. Wearing respiratory protective equipment, like dust masks, can minimize the risk of respiratory issues.

Jackhammers are formidable tools that play a vital role in construction, demolition, and roadwork projects. Their power and precision make them invaluable in various industries.

By adhering to safety guidelines, proper maintenance, and understanding the potential health consequences, we can harness the power of jackhammers while safeguarding our well-being. Embrace the versatility and force of the jackhammer responsibly, and let it be your steadfast companion in conquering the toughest of tasks.

The jackhammer’s origins trace back to the mid-19th century, with Charles Brady King’s pneumatic drill patent in 1849. It gained prominence for tunneling and mining.

A jackhammer is a versatile construction tool used for breaking hard materials like concrete, rocks, and pavement. It’s vital in construction, demolition, and roadwork projects.

The term “jackhammer” likely originates from its hammering action and the use of “jack,” signifying a mechanical device. The name reflects its percussive force.

A jackhammer consists of crucial components: the power source (pneumatic, electric, or hydraulic), the heavy piston, drill bit, handle, and often vibration dampening mechanisms.

To jackhammer cement, first, put on safety gear. Position the drill bit on the cement surface, hold the handle firmly, and let the hammer’s weight do the work. Apply controlled pressure to break the cement.

Jackhammers come in three main types: pneumatic, electric, and hydraulic. Pneumatic uses compressed air, electric needs electricity, and hydraulic relies on hydraulic power.

Not all jackhammers require electricity. Pneumatic jackhammers use compressed air, while hydraulic versions utilize hydraulic power, making them versatile in various settings.

Jackhammers offer efficiency and precision in breaking hard materials. They excel in construction, demolition, and roadwork, saving time and labor compared to manual methods.