Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

How does Wonder Wire work? Unlock the secrets of this extraordinary material that’s revolutionizing industries. From its ingenious design to mind-boggling applications, Wonder Wire’s conductivity and flexibility will leave you in awe. Curious to explore the wonders it holds? Get ready to dive into a guide that reveals the magic behind this incredible innovation.

Whether you’re an engineer or simply intrigued by cutting-edge technologies, understanding how Wonder Wire works will ignite your curiosity and spark your creativity. Let’s unravel the mysteries together and embark on a journey that unveils the power of Wonder Wire

Key Summary: How Does Wonder Wire Work?

Wonder Wire operates by using cutting-edge technology to provide seamless and efficient communication solutions. It offers a streamlined process for transmitting data, enabling users to connect effortlessly across various platforms.

Wonder Wire, the enigmatic material that combines strength and flexibility, has sparked curiosity among many. In this comprehensive guide, we will take an analytical journey through the inner workings of Wonder Wire and explore a step-by-step approach to using it effectively.

Before we embark on the step-by-step guide, let’s unravel the magic that makes Wonder Wire so exceptional. Wonder Wire is a cutting-edge innovation born from the synergy of advanced materials and scientific principles. Its unique composition of specially engineered polymers and conductive elements enables it to conduct electricity efficiently while maintaining robust structural integrity.

To begin, familiarize yourself with Wonder Wire’s appearance and texture. It may seem ordinary at first glance, but its extraordinary capabilities lie beneath the surface. Take note of its flexibility, as this characteristic will be crucial in later steps.

Wonder Wire finds application in various industries, from aerospace to healthcare. Determine the specific purpose you have in mind for using Wonder Wire. Whether it’s for electronic circuits, medical devices, or renewable energy systems, identifying the right application is key to harnessing Wonder Wire’s full potential.

Before diving into the hands-on process, prioritize safety. Wonder Wire conducts electricity, so ensure you are wearing appropriate safety gear, including insulated gloves and goggles, to protect yourself from potential electrical hazards.

Now, it’s time to measure the required length of Wonder Wire for your application. Use a measuring tape to ensure precise measurements. Once measured, use a sharp pair of wire cutters to cut the Wonder Wire to the desired length.

Most applications require the wire to be stripped of its insulation at both ends. Use wire strippers to gently remove the outer insulation, exposing the conductive core. Be cautious not to damage the inner wires during this process.

With the wires stripped, it’s time to connect Wonder Wire to your application. Whether you’re creating an electronic circuit or incorporating it into a medical device, follow the specific connection guidelines for your application. Take advantage of Wonder Wire’s flexibility to maneuver it into position with ease.

Once the connections are in place, ensure they are secure. Depending on your application, you may use soldering techniques, crimping, or specialized connectors to achieve a reliable and durable connection.

Before finalizing your project, perform thorough testing to ensure the Wonder Wire is functioning as intended. Use appropriate testing equipment and methods to verify the electrical conductivity and overall performance. If any issues arise during testing, troubleshoot the connections and rectify any discrepancies.

With your Wonder Wire project successfully completed, take a moment to admire the wonders of this extraordinary material. Its seamless combination of strength and flexibility makes it a versatile and valuable addition to numerous applications.

Wonder Wire opens doors to endless possibilities. Embrace innovation and creativity as you explore new ways to leverage Wonder Wire’s potential. Share your discoveries with the world, inspiring others to tap into the magic of Wonder Wire.

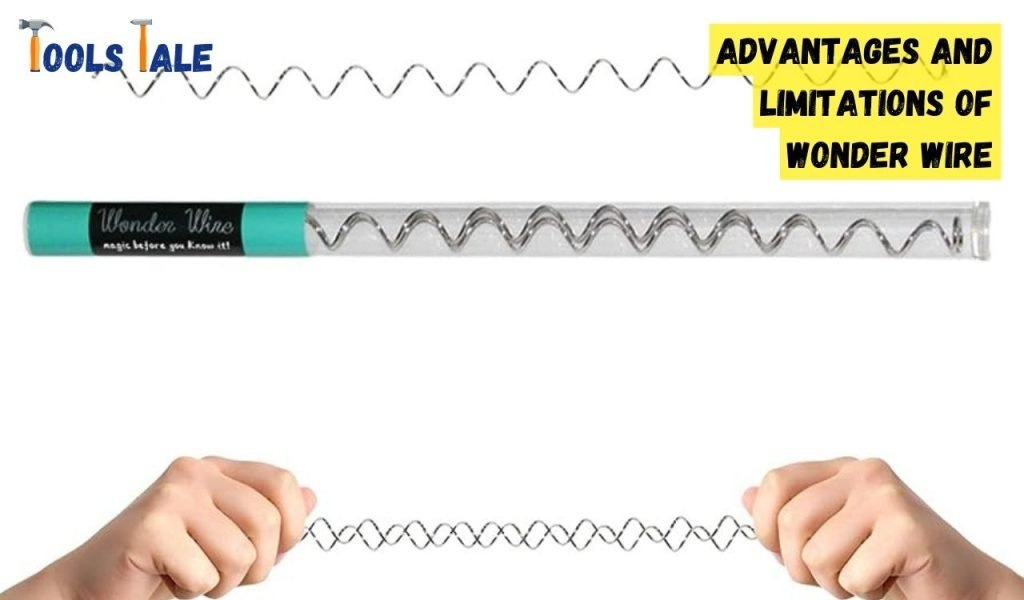

Wonder Wire, with its unparalleled combination of strength and flexibility, has earned its place as a revolutionary material in various industries. As we embark on an analytical journey, let’s explore the advantages that Wonder Wire brings to the table, as well as the limitations that warrant consideration.

Wonder Wire’s distinctive properties make it a game-changer in the world of materials engineering. Its high conductivity, flexibility, and durability offer an array of advantages across industries, propelling advancements in technology and sustainable solutions. Acknowledging its limitations while harnessing its potential enables us to fully appreciate the marvel of Wonder Wire and all it has to offer.

Understanding how Wonder Wire works is only half the equation; ensuring its optimal performance requires diligent maintenance and adherence to best practices. In this comprehensive guide, we will delve into the essential aspects of maintaining Wonder Wire and explore the best practices that maximize its potential.

Routine inspections play a crucial role in preserving Wonder Wire’s functionality. Periodically examine the wire for signs of wear, damage, or corrosion. Address any issues promptly to prevent potential failures. Additionally, keep Wonder Wire clean by gently wiping it with a soft, dry cloth to remove dirt and debris that may hinder its conductivity.

Wonder Wire’s flexibility is undoubtedly an advantage, but it also means it is susceptible to physical stress. Avoid bending or twisting Wonder Wire beyond its recommended limits, as excessive strain can compromise its integrity. When integrating Wonder Wire into applications, ensure proper supports and protections are in place to prevent undue stress on the wire.

Wonder Wire’s performance may be influenced by temperature fluctuations. Take into account the operating temperature range of Wonder Wire in your applications and ensure it remains within the specified limits. Extreme temperatures may impact its conductivity and mechanical properties, so careful planning is essential.

Properly securing connections is critical to the reliable performance of Wonder Wire. Whether soldering, crimping, or using connectors, ensure that connections are stable and secure. Loose connections may lead to electrical resistance and signal disruptions, impacting the overall efficiency of your applications.

During handling and storage, exercise care to avoid unnecessary stress on Wonder Wire. Store it in a clean, dry environment away from direct sunlight and corrosive substances. Coiling Wonder Wire when not in use can prevent tangling and damage.

Always follow the manufacturer’s guidelines and recommendations for using and maintaining Wonder Wire. Manufacturer specifications provide valuable insights into optimizing the wire’s performance and ensuring safety.

When incorporating Wonder Wire into applications, consider the surrounding environment. Ensure that the wire is shielded from potential hazards, such as chemicals or sharp objects, that could compromise its integrity. Taking these precautions extends the lifespan of Wonder Wire and enhances its reliability.

Properly trained personnel should handle Wonder Wire during installation and maintenance. Ensure that individuals working with the wire understand its properties and the necessary safety precautions. A knowledgeable and skilled team guarantees that Wonder Wire is utilized effectively and safely.

Regularly conduct performance testing to assess Wonder Wire’s electrical conductivity and mechanical integrity. This allows you to identify any potential issues early and take corrective measures promptly. Testing also provides valuable data for optimizing your applications.

Maintain comprehensive records of Wonder Wire installations, maintenance activities, and any issues encountered. Documentation assists in tracking the wire’s performance over time and supports informed decision-making.

Safety is of utmost importance when working with Wonder Wire, as it involves handling electrical components. Here are crucial safety considerations to ensure a secure and risk-free experience:

Due to Wonder Wire’s conductivity, it is essential to take electrical safety precautions seriously. Always disconnect power sources and de-energize circuits before handling the wire. This prevents accidental shocks and ensures your safety while working with electrical components.

Wearing the appropriate Personal Protective Equipment (PPE) is essential when handling Wonder Wire. Insulated gloves, safety goggles, and protective clothing shield you from potential injuries and electrical hazards. Prioritize your safety by using the correct PPE for the task at hand.

While Wonder Wire’s flexibility is advantageous, it also makes the wire susceptible to physical stress. Avoid excessive bending, twisting, or pulling, as this can lead to wire damage or failure. Properly secure and support the wire to prevent any physical strain that may compromise its structural integrity.

Temperature considerations are crucial for Wonder Wire applications. Extreme temperatures can impact the wire’s electrical properties and overall performance. Ensure that the wire operates within the specified temperature range to maintain efficiency and longevity.

Proper installation is vital for the safe and reliable performance of Wonder Wire. Follow the manufacturer’s guidelines and industry best practices during installation. Avoid sharp bends or tight corners, and use appropriate connectors to ensure secure connections.

In environments where Wonder Wire may encounter corrosive substances, protective measures are essential. Avoid exposing the wire to chemicals that could compromise its materials or coating. If necessary, use protective sheathing to shield the wire from harmful substances.

Before using Wonder Wire, conduct a thorough risk assessment of the application and potential hazards. Ensure that all personnel involved in handling the wire receive proper training and understand the safety protocols. Regularly review safety procedures to maintain a safe work environment.

Always be prepared for any unforeseen incidents. Have a first aid kit readily available and ensure that personnel are trained in basic first aid procedures. Quick and appropriate response to injuries can mitigate potential harm.

Wonder Wire’s remarkable properties make it a game-changer in various industries. However, it comes with a responsibility to prioritize safety and adhere to best practices. By following electrical safety precautions, using proper Personal Protective Equipment (PPE), and handling Wonder Wire with care, you can ensure a secure and efficient experience.

Remember to consider temperature limits, secure connections, and avoid physical stress to maintain its optimal performance. Embrace Wonder Wire’s potential responsibly, and it will undoubtedly unlock wonders in your applications.

Wonder Wire is a specialized type of wiring that offers exceptional versatility and performance. It is engineered to provide efficient electrical conductivity while being highly flexible, making it suitable for various applications.

Wonder Wire’s unique construction combines advanced materials to ensure optimal electrical conductivity. Its design allows for seamless transmission of electrical signals or power, making it an ideal choice for diverse electronic and electrical setups.

Using Wonder Wire is straightforward. Simply incorporate it into your electrical circuit or setup, following standard wiring practices. Its flexibility and adaptability make installation and connection processes more convenient, even in complex configurations.

Yes, Wonder Wire is designed to withstand a wide range of temperatures. Its materials are carefully selected to ensure stability and functionality in both high-temperature and low-temperature environments, making it suitable for various industries and conditions.

Absolutely, Wonder Wire is crafted with durability in mind. Its construction is engineered to resist wear, tear, and degradation over time, resulting in a longer lifespan. This durability makes it a reliable choice for projects requiring sustained performance.

Yes, Wonder Wire is well-suited for renewable energy applications. Its efficient conductivity and robust design make it compatible with various components and systems used in renewable energy setups, contributing to enhanced energy transmission and utilization.