Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Looking to bring transparency and craftsmanship together in your projects? That’s where “How to attach plexiglass to wood” comes in! This guide is your secret sauce to seamlessly bonding the strength of wood with the clarity of plexiglass. Whether you’re a DIY enthusiast or a seasoned woodworker, this simple yet essential skill opens up a world of possibilities.

From creating stunning furniture accents to crafting display cases, we’ve got you covered. No need for complex jargon or hours of frustration – we’ll break it down step by step. So, grab your tools and let’s dive into the art of marrying these two materials like a pro!

Key Summary: How to Attach Plexiglass to Wood?

Attach plexiglass to wood securely using adhesives or mechanical fasteners. The process typically takes under an hour. Ensure proper ventilation and protective gear for safety. Regular cleaning with mild solutions maintains the bond and clarity, ensuring a lasting fusion of strength and transparency.

Plexiglass, a versatile transparent acrylic material, and manufactured wood, a classic and widely-used building material, can cohesively come together to create exceptional projects. The key to a successful partnership lies in understanding their compatibility and the right approach to their combination.

Selecting the appropriate adhesive is paramount to achieving a strong and enduring bond between plexiglass and wood. Acrylic adhesives are often the best choice, specially formulated to adhere effectively to plexiglass while also bonding well with wood. Following the adhesive manufacturer’s guidelines regarding application and curing is critical for a secure and lasting connection.

Preparing the surfaces of both materials is a crucial step in enhancing their compatibility. Ensuring that the surfaces are clean, smooth, and free of any impurities or contaminants is essential. Lightly sanding both the wood and plexiglass surfaces promotes better adhesion.

Considering the differential behavior of wood and plexiglass due to temperature and humidity changes is vital. Wood tends to expand and contract with variations in these factors, while plexiglass remains relatively stable. To accommodate this difference and maintain the bond, leaving a slight gap or utilizing a flexible adhesive is recommended.

In certain applications, incorporating mechanical fasteners such as screws or bolts alongside the adhesive can bolster the bond’s strength and stability. Strategically placing these fasteners ensures an even distribution of stress, reducing the risk of cracking or splitting.

Beyond the technical aspects, integrating plexiglass and wood offers exciting design possibilities. Careful consideration should be given to ensuring that the adhesive and attachment methods complement the overall aesthetics, enhancing the visual appeal of the final project.

Achieving compatibility between plexiglass and wood involves a thoughtful approach, considering adhesion methods, surface preparation, material behaviors, mechanical reinforcement, and design aesthetics. By understanding the unique properties of both materials and adhering to best practices, you can successfully combine plexiglass and wood, resulting in durable, visually pleasing, and innovative projects.

Plexiglass, a lightweight and versatile acrylic material, offers clarity and durability, making it a popular choice for various applications. Attaching plexiglass to wood requires precision and the right approach to ensure a secure and lasting bond. Here’s a step-by-step guide to walk you through the process:

Measure and mark the desired dimensions on both the plexiglass and wood using a measuring tape and pencil. Ensure precision in measurements for a seamless fit.

Carefully cut the plexiglass along the marked lines using a saw or appropriate cutting tool. Employ a fine-toothed saw to prevent chipping and maintain a clean edge.

Use sandpaper or a sanding block to smooth the edges of the cut plexiglass. Gently sand in one direction to avoid creating rough spots.

If the wood surface is rough or uneven, sand it to create a smooth and clean surface for attachment. Remove any splinters or imperfections.

Clean both the plexiglass and wood surfaces with a cleaning solution and cloth to remove any dust, dirt, or residues that might hinder adhesion.

Choose an adhesive specifically designed for bonding acrylic materials. Opt for a clear and strong adhesive that ensures a secure attachment.

Apply a thin, even layer of the selected adhesive on the side of the plexiglass that will attach to the wood. Avoid applying too much adhesive to prevent it from seeping out when pressure is applied.

Carefully position the plexiglass on the desired location on the wood surface, aligning it according to your earlier markings.

Apply even pressure on the plexiglass to ensure a strong bond. Use clamps to hold the plexiglass securely in place while the adhesive cures. Follow the adhesive manufacturer’s recommended curing time.

Ensure that the plexiglass is aligned correctly and adjust its position if needed before the adhesive sets.

If additional support is desired, consider using screws or bolts as mechanical fasteners. Pre-drill holes through the plexiglass into the wood, then secure with screws or bolts.

If any adhesive has seeped out, carefully remove it using a damp cloth before it dries.

Allow the adhesive to fully cure according to the manufacturer’s instructions before moving or using the attached plexiglass and wood.

Inspect the attachment to ensure a secure bond. If satisfied, you can further finish the wood or plexiglass to enhance the overall appearance.

Attaching plexiglass to wood involves careful preparation, selection of appropriate materials, and meticulous application of adhesive. By following this step-by-step guide, you can achieve a secure and durable bond between plexiglass and wood for your desired projects.

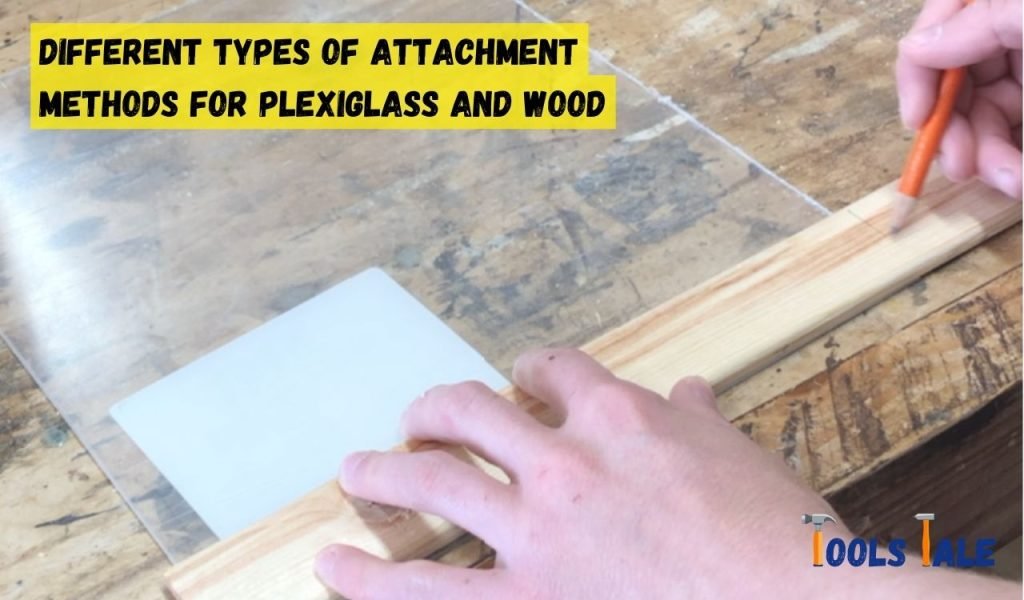

Attaching plexiglass to wood requires choosing an appropriate attachment method that ensures a secure and lasting bond. Here are various methods to achieve this connection:

Choosing the right attachment method depends on the specific application, load-bearing requirements, aesthetic preferences, and the level of permanence desired. By considering these options, you can effectively and securely attach plexiglass to wood for a wide range of projects.

Working with plexiglass, a versatile and durable acrylic material, requires proper safety measures to ensure a safe and accident-free working environment. Here are essential precautions to follow:

Prioritizing safety when working with plexiglass is crucial for preventing injuries and ensuring a successful and enjoyable project. By following these safety precautions, you can create your plexiglass projects with confidence and minimize any potential risks associated with handling this versatile material.

When attaching plexiglass to various surfaces, several common challenges can emerge, potentially affecting the outcome of the project. Being aware of these issues and understanding how to address them is essential for a successful attachment process. Here are some of the most prevalent concerns and ways to overcome them:

Understanding and addressing these common attachment challenges is essential for achieving a successful and long-lasting connection between plexiglass and other surfaces.

By following proper preparation, using suitable adhesives, ensuring accurate alignment, and being cautious with temperature and application, you can mitigate these issues and achieve a secure and aesthetically pleasing attachment of plexiglass in your projects.

Completing a successful attachment of plexiglass to wood involves careful consideration of finishing touches and ongoing maintenance to ensure durability, aesthetics, and longevity. Here are essential steps and tips for these crucial aspects:

Applying the finishing touches and implementing proper maintenance practices are vital for preserving the quality and aesthetics of plexiglass attachments. By adhering to gentle cleaning techniques, protecting against damaging agents, and conducting regular inspections, you can enjoy a lasting and attractive plexiglass attachment that enhances your project’s overall appearance and functionality.

Attaching plexiglass to wood demands precision, suitable materials, and cautious application. Follow steps diligently, opt for the right adhesive, and prioritize safety. A seamless bond, smoothed edges, and proper maintenance ensure a durable, aesthetically pleasing collaboration.

Whether crafting for practicality or artistry, this fusion of plexiglass and wood can elevate projects, offering transparency and structural integrity. Embrace the art and science of attachment, and your creations will stand as a testament to this harmonious combination. Happy crafting!

Yes, plexiglass can be glued to wood effectively. The key is using specialized acrylic adhesives designed to create a strong and lasting bond between plexiglass and wood. Proper surface preparation, ensuring the surfaces are clean and dry, is crucial for achieving a reliable attachment. Additionally, align the plexiglass carefully with the wood before applying the adhesive for the best results.

The best method is using acrylic-compatible adhesives designed for bonding plexiglass to various surfaces. Follow the manufacturer’s instructions for optimal results.

Attaching plexiglass to woodworking involves employing acrylic-compatible adhesives. These adhesives are designed to adhere well to both plexiglass and wood. Ensuring the surfaces are clean, smooth, and dry before applying the adhesive is crucial. Following the adhesive manufacturer’s guidelines for application and curing is essential to achieve a secure bond.

Yes, epoxy glue can be suitable for attaching plexiglass to wood, provided it’s compatible with both materials. Ensure the epoxy is transparent and formulated for acrylic bonding.

No, adding acetone when gluing plexiglass to wood is not recommended. Acetone can damage plexiglass and is not necessary for achieving a strong bond between plexiglass and wood. It’s best to use adhesives specifically designed for bonding acrylics, following the manufacturer’s instructions for surface preparation and application to ensure a secure and reliable attachment.

Hot glue is not the most ideal choice for bonding plexiglass to wood. Hot glue may not provide a strong and durable bond, and it may not effectively adhere to plexiglass. Opt for specialized acrylic adhesives that are designed to bond plexiglass and wood, ensuring a lasting and secure attachment.

For attaching plexiglass to wood, the best choice is a clear, acrylic-based wood glue. This type of wood glue is designed to bond well with both wood and acrylic materials. It provides a strong and transparent bond, ensuring a seamless attachment between the plexiglass and the wood. Always check for compatibility and follow the manufacturer’s instructions for the best results.