Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

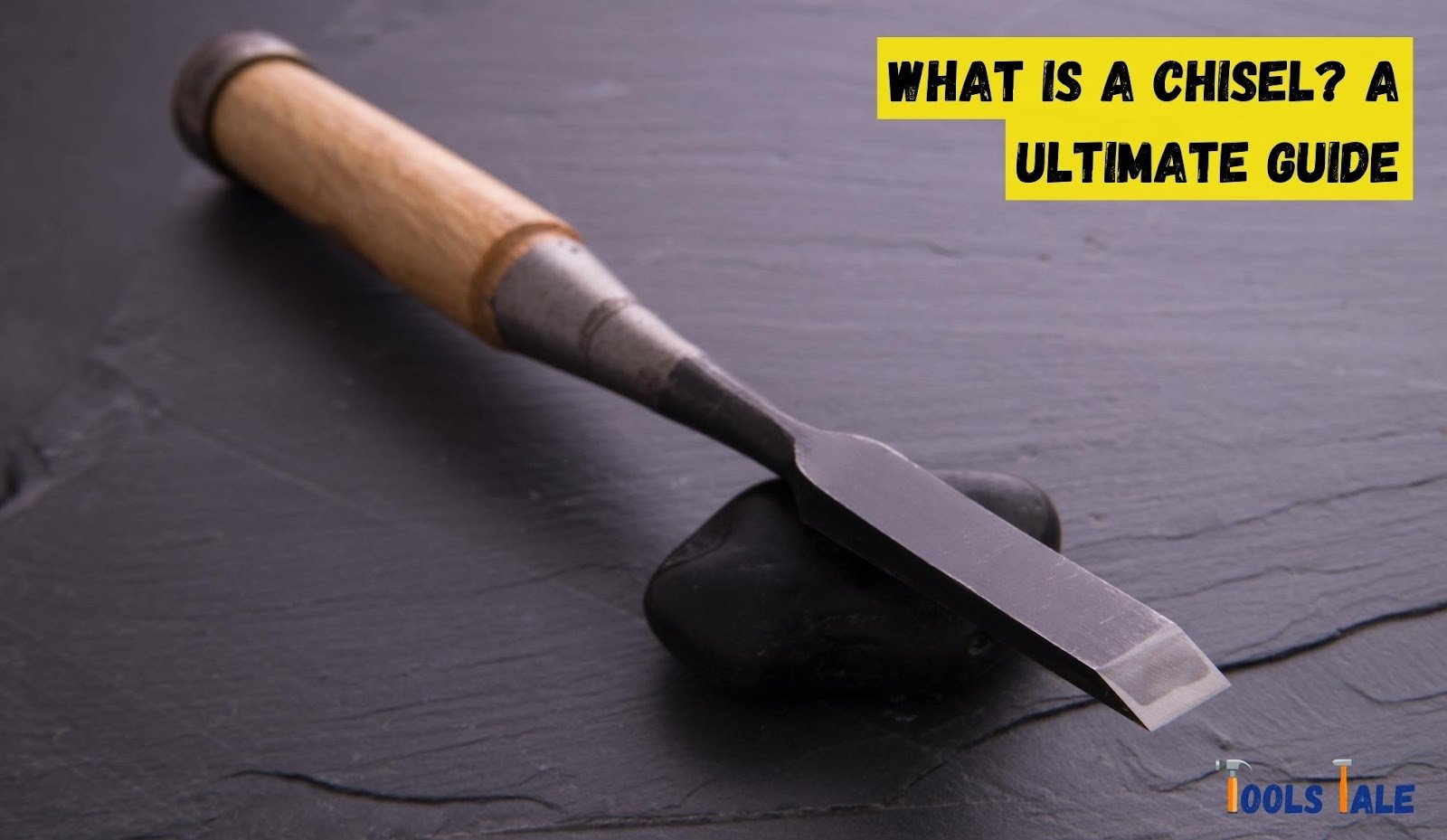

What is a chisel? If you’ve ever wondered about this versatile tool that holds the key to unlocking your woodworking potential, you’re in for a treat. From shaping wood to carving intricate designs, a chisel is a craftsman’s best friend.

In this guide, we’ll unravel the mystery behind chisels, revealing their various types, uses, and essential tips to get you started. So, grab your tool belt and let’s embark on an exciting journey of chisels and craftsmanship!

Key Summary: What is a Chisel?

A chisel is a cutting tool used in woodworking and craftsmanship. It’s designed to shape and remove materials like wood, stone, or metal. Learn about types, uses, and essential tips in this comprehensive guide. Unleash your woodworking prowess today!

A chisel is a timeless and invaluable hand tool, integral to craftsmanship for centuries. Comprising a sharp blade and a handle, it finds use in woodworking, masonry, metalworking, and sculpture. With precision and versatility, a chisel effortlessly cuts and carves materials, delivering clean and accurate results.

Its history reaches back to ancient civilizations, where it contributed to magnificent structures and artworks. In modern times, artisans and DIY enthusiasts continue to cherish its ability to add artistry to their creations. While woodworking is its primary domain, a chisel’s capabilities extend to diverse materials, allowing craftsmen to explore boundless possibilities.

As artisans wield this ageless tool, they infuse their style and personality into their work, creating handcrafted masterpieces that stand out with authenticity. Beyond utility, a chisel symbolizes the preservation of tradition, skill, and the human spirit’s creative essence. It is a reflection of the enduring bond between creators and their craft, celebrating the timeless allure of artistic chiseling.

Chisels offer a multitude of benefits that make them an indispensable tool in various trades and artistic endeavors. From woodworking to metalworking, their versatility and precision elevate craftsmanship to new heights. Let’s explore the key advantages of using chisels:

One of the most significant benefits of chisels is their unparalleled precision and control. Unlike power tools, chisels allow craftsmen to work with finesse and delicacy, especially when dealing with intricate designs or detailed work. The sharpness of the blade and the ability to guide the tool by hand result in clean and precise cuts, ensuring a high level of craftsmanship in every project.

Chisels showcase remarkable versatility, capable of handling a wide range of materials. From wood and stone to metal and plastic, a chisel can cut and shape diverse mediums with ease. This adaptability makes it an ideal choice for various projects, whether it’s carving ornate designs in wood or sculpting intricate metalwork.

Investing in a high-quality chisel pays off in the long run. Chisels, when well-maintained, exhibit impressive durability and can withstand rigorous use without losing their edge. The blade’s composition, often made of high-carbon steel and subjected to precise heat treatment, ensures a lasting tool that can tackle demanding tasks for years to come.

Chisels empower craftsmen to infuse their unique style and personality into their work. Unlike mass-produced items, handcrafted pieces using chisels exude individuality and charm, captivating admirers with their artistic flair. The satisfaction and pride of creating one-of-a-kind masterpieces are unmatched, making chiseling an essential avenue for artistic expression.

When using a chisel, craftsmen have full control over the depth and detail of their cuts. This level of control is especially beneficial in woodworking and sculpting, where intricate details and delicate lines are essential to achieving the desired outcome. Chisels allow artisans to create depth and texture, adding depth and dimension to their creations.

Unlike power tools that rely on electricity or batteries, chisels are hand-operated, requiring no external power source. This advantage makes them ideal for remote or outdoor projects where access to electricity may be limited. It also provides a quieter and more intimate working environment, allowing artisans to fully immerse themselves in their craft.

Chisels, when used correctly, offer a safe working experience. Unlike power tools with moving parts, the risk of accidents is relatively low with hand-operated chisels. Additionally, maintaining a chisel is straightforward, involving regular sharpening and occasional lubrication. This simplicity makes it an accessible tool for artisans of all skill levels.

Using chisels embraces a tradition that dates back centuries, connecting present-day artisans with the craftsmanship of generations past. Embracing this time-honored tool pays homage to the heritage of artistic expression and celebrates the timeless appeal of handcrafted work, preserving craftsmanship for future generations.

A chisel is a finely crafted tool composed of several essential components, each playing a crucial role in its functionality and effectiveness. Understanding these components is fundamental for both using the chisel efficiently and maintaining its longevity. Let’s explore the key components that make up a chisel:

The blade is the heart of the chisel, responsible for cutting and shaping materials. Typically made of high-quality steel, the blade’s sharp edge is essential for achieving clean and precise cuts. The process of crafting the blade involves precise heat treatment to achieve optimal hardness and edge retention, ensuring it remains sharp through extended use.

The tang is the part of the blade that extends into the handle. It plays a vital role in providing stability and ensuring a secure connection between the blade and the handle.

A chisel’s tang can come in different configurations, including full tang and partial tang. A full tang chisel, where the tang extends through the entire handle, is generally considered more durable and less prone to breakage under pressure.

The handle serves as the grip, allowing the user to hold and control the chisel during operation. Handles are available in various materials, with wood and plastic being common choices.

The handle’s ergonomic design is crucial for providing comfort during prolonged use, reducing hand fatigue, and improving precision. A well-designed handle ensures a comfortable and secure grip, allowing artisans to work with ease and confidence.

The butt is the end of the handle opposite the blade. Although seemingly simple, the butt is a critical component that plays a role in the chisel’s balance and control. It acts as a counterbalance to the blade, providing stability and control while using the tool. Additionally, the butt allows artisans to strike the chisel with a mallet or hammer for tasks requiring more substantial cutting force.

The bevel refers to the sloped or angled surface on one side of the chisel’s blade. It is an essential feature that affects the cutting performance and versatility of the tool. Chisels can have different bevel angles, with each angle influencing how the chisel interacts with specific materials.

Lower bevel angles are more suitable for soft materials like wood, providing cleaner cuts, while higher bevel angles are better suited for tougher materials like metal or stone, offering improved durability and strength.

The shoulder is the part of the blade where the bevel transitions to the flat back of the chisel. It plays a role in defining the cutting edge’s sharpness and precision, with a well-defined shoulder contributing to cleaner and more controlled cuts.

Some chisels come with a striking cap, a metal cap that covers the top end of the handle. The striking cap serves as additional protection for the handle when the chisel is struck with a hammer or mallet. This feature helps prevent handle damage and increases the chisel’s durability during heavy-duty applications.

In the world of hand tools, chisels stand out as versatile cutting and carving instruments. While they share similarities with certain tools, chisels have distinct features that set them apart. Let’s explore the key differences between chisels and similar tools:

Chisels and gouges are both carving tools used for cutting and shaping materials, particularly in woodworking and sculpting. However, their main difference lies in their cutting edges. Chisels have straight blades, ideal for making flat cuts and cleaning flat surfaces.

On the other hand, gouges have curved blades, making them perfect for carving rounded or concave shapes. Both chisels and gouges complement each other, providing artisans with a comprehensive set of tools for a wide range of carving tasks.

Chisels and punches share some similarities in appearance, both having a sharp end. However, their primary functions are distinctly different. A chisel is designed for cutting and shaping materials, while a punch is specifically used for creating holes or indentations in materials.

Punches come in various shapes and sizes to suit different hole diameters and shapes, providing craftsmen with precise control when creating holes or markings.

Although chisels and screwdrivers may look similar to some extent, their purposes are entirely different. A screwdriver is specifically designed for driving screws into materials or removing them. On the other hand, a chisel is intended for cutting, carving, or shaping materials.

Attempting to use a chisel as a screwdriver or vice versa can lead to damage to both the tool and the material being worked on. It’s essential to use each tool for its designated purpose to achieve optimal results and prevent accidents.

Chisels and knives both have sharp blades, but they differ in their primary use and design. Knives are versatile cutting tools used for various tasks, from food preparation to utility purposes.

On the other hand, chisels are more specialized for cutting and shaping materials like wood, stone, and metal in craftsmanship and artistic applications. Chisels have broader and thicker blades compared to knives, providing more stability and control for precise cuts in specific materials.

While chisels are used for cutting and carving, rasps and files are abrasive tools used for shaping and smoothing materials. Rasps feature rough, sharp-edged surfaces used for rapid material removal, ideal for rough shaping and contouring.

Files, on the other hand, have finer abrasive surfaces used for smoothing and refining surfaces after rough shaping. Chisels, rasps, and files serve different stages in the crafting process, each contributing to achieving the desired final form and finish.

Chisels come in a variety of types, each specially designed for specific tasks and materials. Understanding the different types of chisels is essential for selecting the right tool for your woodworking and craftsmanship needs. Let’s explore the key types of chisels:

Bench chisels are the most common and versatile type of chisels used in woodworking. They feature beveled edges and come in various widths, ranging from 1/4 inch to 2 inches or more.

Bench chisels are ideal for general woodworking tasks, such as paring, mortising, and chopping. They are a go-to choice for many craftsmen due to their versatility and ability to handle a wide range of cutting and shaping tasks.

Mortise chisels are specifically designed for cutting mortises, which are rectangular holes used in joinery. They have thick, sturdy blades with square edges, making them suitable for chopping out precise and clean mortises in wood. Mortise chisels are essential for creating strong and accurate joints in woodworking, ensuring the structural integrity of the final piece.

Paring chisels have long, thin blades and are used for delicate tasks that require high precision. They excel in trimming and shaping wood with utmost accuracy, making them indispensable for fine woodworking and detailed craftsmanship. Paring chisels are perfect for achieving clean and smooth cuts on surfaces where bench chisels might be too wide or bulky.

Firmer chisels, also known as bevel edge chisels, have a sturdy construction and are well-suited for heavy-duty tasks. They are used for removing large amounts of material and are commonly employed in carpentry and rough woodworking projects. Firmer chisels are ideal for tasks where strength and durability are paramount, such as chopping out deep mortises or rough shaping tasks.

Butt chisels are compact chisels with short blades and are often used in tight spaces or for delicate work. They are particularly useful for trimming and fitting joints in cabinetry and furniture making. Butt chisels provide excellent control in confined spaces, allowing craftsmen to make precise cuts in areas where larger chisels might not be suitable.

Japanese chisels, also known as nomi, have a distinctive design with a laminated blade and a hollow-ground back. They are renowned for their sharpness and are used in traditional Japanese woodworking.

Nomis come in various shapes and sizes, each serving specific purposes in the intricate art of Japanese joinery. The careful craftsmanship and attention to detail in Japanese chisels make them highly sought after by woodworking enthusiasts worldwide.

Corner chisels have a unique L-shaped design and are used for cutting square corners or removing material in tight corners and recesses. They are valuable tools for joinery work, especially when creating precise 90-degree angles in woodworking projects.

While gouges may not be strictly categorized as chisels, they are essential carving tools often used alongside chisels. Gouges have curved blades, allowing craftsmen to create intricate and rounded cuts in wood and other materials. They are particularly useful in relief carving and shaping concave surfaces.

Skew chisels have angled blades, making them suitable for precise and controlled cuts in wood and other materials. They are often used for smoothing and finishing surfaces, and their unique design allows craftsmen to achieve clean and accurate bevels on wood.

Using a chisel effectively requires skill, precision, and understanding of proper techniques. Whether you are a novice woodworker or an experienced craftsman, mastering the art of using a chisel will enhance your woodworking projects and allow you to create intricate and refined designs. Let’s delve into the essential steps and techniques for using a chisel:

Before starting, mark the area on the material where you intend to make your cut or carve. Use a pencil or marking knife to create precise guidelines, ensuring accurate results. Measuring and marking the material beforehand will help you stay on track and achieve your desired design.

Ensure that the material you are working on is securely clamped or held in place. This prevents the material from moving during chiseling, reducing the risk of accidents and ensuring that your cuts remain precise and clean. Securing the material is particularly important when using a mallet or hammer to strike the chisel.

Hold the chisel firmly with one hand while using the other hand to guide it. The beveled edge of the chisel should face down, and the chisel’s handle should be at a slight angle to the surface you are cutting. The angle of the chisel’s handle depends on the desired depth and angle of your cut.

When starting a cut, begin with light, controlled pressure to create a shallow groove. This initial groove will act as a guide for deeper cuts and help prevent the chisel from slipping. Gradually deepen the cut with additional passes until you reach the desired depth.

For heavy-duty tasks or when cutting mortises, use a mallet or hammer to strike the chisel’s handle. The force from the mallet or hammer allows you to make deeper and more forceful cuts. Ensure that the force is applied evenly and directly above the chisel to prevent damage to the blade or handle.

When working with wood, pay attention to the direction of the grain. Cutting against the grain may cause tear-out and splintering, leading to unsightly results. Always work with the grain to achieve cleaner and smoother cuts.

For deeper cuts, gradually increase the pressure and depth of the chisel. Avoid forcing the chisel too deep in a single pass, as this may cause the chisel to get stuck or result in uneven cuts. Take your time and make multiple passes to achieve the desired depth.

For fine and precise cuts, switch to paring chisels. Paring chisels have thin blades that allow you to remove thin layers of material with precision. They are ideal for achieving smooth and clean surfaces on your woodworking projects.

Always prioritize safety when using a chisel. Wear appropriate safety gear, such as safety goggles and ear protection, to protect yourself from flying debris and loud noises. Keep your hands behind the cutting edge of the chisel to prevent accidental cuts.

Regularly sharpen your chisels to maintain their cutting efficiency. Use sharpening stones or honing guides to keep the chisel’s edge sharp and ready for use. Additionally, keep the chisel’s handle clean and well-maintained to ensure a comfortable and secure grip during use.

Proper maintenance of your chisels is essential to ensure their longevity, cutting efficiency, and overall performance. Regular care and upkeep will keep your chisels in top condition, allowing you to work with precision and confidence in your woodworking projects. Let’s explore the key steps and practices for chisel maintenance:

Maintaining sharp blades is crucial for the cutting performance of your chisels. Regularly sharpen the chisel’s blade using sharpening stones or honing guides. Sharpening removes dull edges and nicks, ensuring that the chisel cuts smoothly and cleanly through materials.

In addition to sharpening the beveled edge, it’s essential to flatten the back of the chisel. A flat back ensures even contact with the sharpening stone, enhancing the blade’s overall sharpness. Use a honing guide or a flat surface with abrasive paper to flatten the back of the chisel.

When not in use, protect the chisel’s sharp edge with blade guards or blade sleeves. This simple step prevents accidental nicks or damage to the edge during storage. Avoid placing chisels in a toolbox or drawer without protection, as they may come into contact with other tools and surfaces.

If your chisel has a wooden handle, periodically apply linseed oil or another wood preservative to keep the handle in good condition and prevent cracking or drying out. Properly maintained wooden handles provide a comfortable and secure grip during use.

Using the chisel correctly also contributes to its maintenance. Avoid prying or leveraging with the chisel, as this can damage the blade and weaken the handle. Instead, use the chisel for cutting and shaping tasks as intended, applying even pressure and letting the sharpness of the blade do the work.

After each use, clean the chisel to remove dust, debris, and any residue. Use a soft brush or cloth to wipe the blade and handle clean. Cleaning the chisel prevents build-up and ensures that the blade remains free from contaminants that could affect its cutting performance.

Store your chisels in a dry and clean environment. Avoid leaving them on damp surfaces or in humid conditions to prevent rust or corrosion. Consider using a chisel roll or wall-mounted tool rack to store your chisels safely and organized.

Handle your chisels with care to avoid accidental drops or impacts that could damage the blade or handle. Avoid striking the chisel’s handle with a metal hammer or mallet, as this can cause handle splintering. Instead, use a wooden or rubber mallet when striking the chisel.

If you notice minor damage, such as small chips or dings in the blade, address them promptly. Use sharpening stones or honing guides to remove minor imperfections before they worsen and affect the chisel’s performance.

Regularly inspect your chisels for signs of wear, damage, or loose handles. Detecting issues early allows you to address them before they become more significant problems. Pay attention to any signs of handle cracks, blade deformation, or loose ferrules.

Using chisels effectively and safely requires careful attention and adherence to proper techniques. Avoiding certain pitfalls and common mistakes will not only protect you from accidents but also ensure the longevity and performance of your chisels. Let’s explore the key things to avoid when using chisels:

Avoid applying excessive force when using a chisel, especially with delicate materials. Let the sharpness and proper technique do the work to achieve precise and controlled cuts. Excessive force can lead to chisel slippage, causing unintended damage to the material or injury to yourself.

Chiseling against the grain of wood can lead to tear-out and splintering, resulting in unsightly and uneven cuts. Always work with the grain to achieve cleaner and smoother results. Take note of the direction of the grain and adjust your chiseling technique accordingly.

Safety should always be a priority when using chisels. Wear appropriate safety gear, such as safety goggles and ear protection, to protect yourself from flying debris and loud noises. Additionally, keep your hands behind the cutting edge to prevent accidental cuts.

Take your time when using chisels, especially for intricate or detailed work. Rushing the process may lead to mistakes and compromise the quality of your craftsmanship. Exercise patience and precision to achieve the desired results.

Avoid using dull chisels, as they can cause frustration and produce subpar results. Regularly sharpen and maintain your chisels to ensure they are in optimal condition for your projects. Dull chisels require more force to cut and can result in imprecise and rough cuts.

Using the chisel at the wrong angle can affect the quality of your cuts. The angle of the chisel’s handle should be adjusted based on the desired depth and angle of the cut. Ensure that the beveled edge of the chisel is properly aligned with the material to achieve clean and accurate cuts.

Using the wrong type or size of chisel for a particular task can lead to inefficiency and potential damage to the chisel or material. Select the appropriate chisel based on the task requirements, such as width, blade shape, and handle length.

Neglecting the maintenance of your chisels can diminish their performance and lifespan. Regularly clean, sharpen, and inspect your chisels to keep them in top condition. Proper maintenance ensures that your chisels are always ready for use when you need them.

The handle of the chisel plays a vital role in providing control and stability during use. Inspect the handle regularly for cracks or damage. A damaged handle can compromise your grip and control, affecting the quality of your cuts.

Chisels are primarily designed for woodworking tasks. Avoid using woodworking chisels for cutting metal or other hard materials, as it can cause premature blade wear and damage the chisel. Invest in appropriate chisels specifically designed for metalworking tasks.

In conclusion, chisels are versatile and indispensable tools in woodworking and craftsmanship. Understanding the different types of chisels, mastering their usage, and maintaining them properly are key to achieving precise and refined results in your projects.

Remember to prioritize safety, avoid common mistakes, and invest in proper chisel maintenance for optimal performance and longevity. With skillful handling and dedication to craftsmanship, chisels can elevate your woodworking endeavors to new heights of excellence. Happy woodworking!

A chisel is a cutting tool used in woodworking and craftsmanship. It is designed to shape, carve, and remove materials such as wood, stone, or metal. Chisels are essential for precise and intricate work.

A chisel works by applying force to the blade’s sharp edge to cut and remove material. The user can strike the chisel with a mallet or hammer, or use hand pressure to create the desired cuts.

There are various types of chisels, including bench chisels, mortise chisels, paring chisels, firmer chisels, and more. Each type is specialized for specific tasks in woodworking and craftsmanship.

While chisels are primarily designed for woodworking, there are chisels specifically made for metalworking. Using a woodworking chisel on metal can damage the blade and is not recommended.

To sharpen a chisel, use sharpening stones or honing guides. Maintain the beveled edge and flatten the back of the chisel. Regular sharpening ensures optimal cutting performance.

When using a chisel, wear safety gear like goggles and ear protection. Avoid applying excessive force and keep hands behind the cutting edge. Proper handling and caution prevent accidents.

Yes, there are specialized chisels designed for specific tasks like carving, mortising, and fine detailing. Using the right chisel for the job ensures better results and efficiency.

Chisels can be used on various materials such as wood, stone, and certain metals. However, specialized chisels are recommended for specific materials to achieve optimal results.

Consider the task, material, and size required for your project. Match the chisel type and size to the specific needs of your woodworking or crafting task.

Avoid using excessive force, chiseling against the grain, neglecting safety precautions, and using dull chisels. Proper technique and maintenance prevent mistakes and ensure quality workmanship.