Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

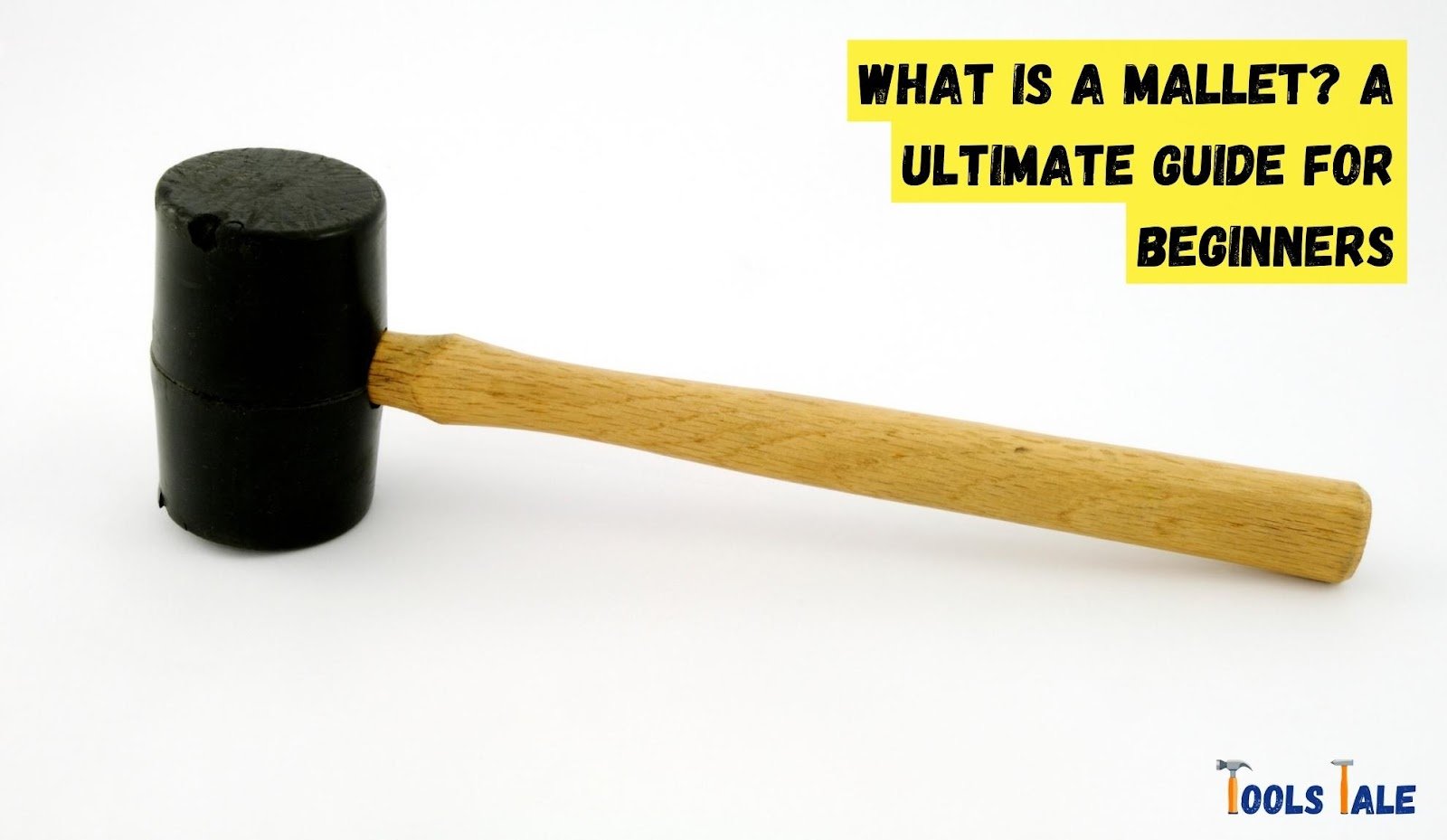

What is a mallet? You might have heard the term, but do you really know what it is? Well, get ready to discover the unsung hero of various tasks! A mallet is not just another hammer wannabe. It’s the secret sauce for precision and finesse in woodworking, metalworking, and more.

Forget the heavy blows of a hammer; a mallet’s got a softer side that won’t leave a mark. From shaping delicate materials to assembling furniture like a pro, this nifty tool is a must-have in your toolbox. So, let’s dive into the world of mallets and unlock their hidden potential!

Key Summary: What is a Mallet?

A mallet is a handheld tool with a large, flat head, typically made of wood or rubber. It is used for striking or driving objects, like chisels or stakes, without damaging them. Mallets are commonly employed in woodworking, metalworking, and construction tasks. Discover its various types and applications.

A mallet is an indispensable hand tool that finds its application across various industries and activities. Comprising a solid head attached to a handle, it facilitates efficient striking and pounding tasks. The head is crafted from materials like wood, rubber, metal, rawhide, or plastic, depending on the intended use and required impact.

Originating from ancient civilizations, early mallet-like instruments were rudimentary, made from stones, wood, or bones, serving tasks like shaping and pounding grains. Advancing civilizations saw mallets gaining prominence in Egypt’s crafts and construction and the Greeks’ carpentry and sculpture.

Today, mallets come in diverse types. Wooden mallets are ideal for woodworking, offering controlled impacts without surface damage. Rubber mallets, non-marring, are perfect for furniture assembly. Dead blow mallets reduce rebound, suitable for delicate tasks. Rawhide mallets work well in metalworking, providing soft yet firm blows.

Mallets feature three main components: the head, handle, and joinery. The head transfers force, while the handle provides grip and control. Joinery techniques like wedging or bonding secure the head to the handle.

Choosing the right mallet entails considering factors like material, weight, handle length, and surface. By understanding mallet nuances, users optimize efficiency and precision in diverse applications, making mallets indispensable tools for professionals and DIY enthusiasts alike.

The history of the mallet is a fascinating journey that traces back to the earliest human civilizations. In ancient times, our resourceful ancestors began crafting rudimentary tools to fulfill their daily needs. These early mallet-like instruments were fashioned from readily available materials such as stones, wood, or bones. They served a variety of functions, from shaping objects to pounding grains in food preparation.

As human civilizations evolved and developed sophisticated techniques, so did the design and usage of mallets. In ancient Egypt, mallets held significant importance and were frequently depicted in artworks. They became essential tools in various crafts and construction projects, facilitating the creation of magnificent structures that still stand as a testament to their expertise.

The legacy of mallets extended to ancient Greek and Roman civilizations, where they found utility in carpentry and sculpture. Skilled artisans and craftsmen wielded mallets with precision to bring their creative visions to life. Through the ages, mallets continued to evolve, adapting to the specific needs of various cultures and industries.

As technological advancements occurred, so did the materials used to craft mallets. The art of metallurgy, for instance, enabled the creation of metal-headed mallets, which offered new possibilities in forging and metalworking. Over time, the versatility of mallets ensured their presence in numerous fields, ranging from woodworking and metalworking to construction and household tasks.

Today, the legacy of mallets lives on, with modern innovations adding new dimensions to their applications. Understanding the rich history and origins of the mallet allows us to appreciate the ingenuity of our ancestors and the enduring significance of this humble yet powerful hand tool. As we continue to rely on mallets for diverse tasks, we pay homage to the timeless tradition of craftsmanship that spans millennia.

Mallets have evolved over time, diversifying into a range of specialized types, each tailored to specific tasks and industries. Let’s explore the various types of mallets available today:

Wooden mallets remain a classic favorite in woodworking and carpentry. Crafted from solid wood, these mallets are renowned for their ability to deliver controlled impacts without causing damage to delicate surfaces. The smooth and firm wooden head ensures precision and accuracy in various woodworking tasks, such as chiseling and joinery.

Rubber mallets are prized for their non-marring properties, making them ideal for tasks that require a softer touch. The head, made from rubber or other soft materials, is perfect for assembling furniture or working with materials that could be damaged by harder blows. Additionally, rubber mallets are commonly used in tasks where an impact needs to be absorbed without leaving marks or imprints.

Dead blow mallets are engineered for tasks that demand minimal rebound and reduced vibrations upon impact. The heads of these mallets are filled with materials like sand or metal shot, which helps absorb and dissipate the force. As a result, dead blow mallets are essential for delicate tasks or when precise, repeatable strikes are necessary, such as when working with delicate materials or aligning parts.

Rawhide mallets feature a head made from rawhide, a material derived from animal hides. The unique properties of rawhide, with its combination of softness and firmness, make these mallets ideal for metalworking and jewelry tasks. Rawhide mallets provide a soft but powerful blow, allowing craftsmen to shape and form metals without leaving marks or damaging the surface.

Plastic mallets are renowned for their versatility and durability. They are lightweight yet sturdy, making them suitable for various household repairs and installations. Plastic mallets are available in different hardness levels, offering users the flexibility to choose the right mallet for their specific project. Additionally, their bright colors help differentiate between different hardness options.

Nylon mallets are known for their non-sparking and non-marring properties, making them valuable in tasks where sparks or damage to surfaces must be avoided. They are widely used in metalworking, where traditional metal hammers could pose safety risks or damage the workpiece.

Copper mallets combine the advantages of a soft striking face with the added benefit of being non-sparking. These mallets are frequently employed in specialized industries like aviation and automotive, where non-sparking tools are required to prevent accidents in volatile environments.

A mallet is a finely crafted tool, carefully designed to ensure optimal performance and longevity. Understanding its components is crucial to appreciating the intricacies of this versatile hand tool. Let’s delve into the key components that make up a mallet:

The head is the business end of the mallet, responsible for delivering the impact to the target surface. It comes in various shapes and materials, each catering to specific applications.

Wooden mallets feature solid wooden heads, which are ideal for woodworking tasks, as they offer a controlled and precise blow. Rubber mallets, on the other hand, have heads made of soft materials, such as rubber, providing a cushioned strike suitable for assembling delicate items.

The handle, also known as the shaft, is the part of the mallet that allows the user to grip and control the tool. Handles are typically made from sturdy materials like wood, fiberglass, or composite materials.

The length and shape of the handle influence the balance and control of the mallet during use. Longer handles provide increased leverage for heavy blows, while shorter handles offer more precision for delicate tasks.

The joinery refers to the method used to attach the head to the handle, ensuring a secure and durable connection. Traditional joinery techniques include wedging, epoxy bonding, or using a metal band to fix the head to the handle. Well-executed joinery enhances the mallet’s overall performance, preventing the head from loosening or separating during use.

An often overlooked but crucial aspect of mallet design is weight distribution. A well-balanced mallet ensures efficient transfer of force, making it easier for the user to control the strikes.

The weight distribution is influenced by the size and material of the head, as well as the length and material of the handle. Manufacturers carefully consider weight distribution to optimize the mallet’s usability and reduce user fatigue.

The handle’s gripping surface is another essential consideration in mallet design. A comfortable and ergonomic grip allows the user to maintain a secure hold on the mallet during repetitive or prolonged tasks. Some mallets feature textured or contoured handles to enhance grip and prevent slipping, providing a more enjoyable and productive user experience.

The finish of the handle affects both aesthetics and functionality. Some mallets have a smooth and polished handle surface, while others may have a rough or textured finish. The choice of handle finish can influence the user’s comfort and grip during prolonged use, as well as the overall appearance of the tool.

Selecting the appropriate mallet for a specific task is a critical aspect of ensuring optimal performance and efficiency. With a diverse range of mallet types available, each tailored to different applications, making the right choice can significantly impact the quality of work. Consider the following factors when choosing the perfect mallet for your needs:

The material of the mallet’s head is a primary consideration. Different materials offer varying degrees of hardness and impact resistance, making them suitable for specific tasks. For woodworking and tasks that require precise control, a wooden mallet is an excellent choice. On the other hand, for assembling furniture or working with delicate materials, a rubber mallet’s soft head will prevent surface damage.

The weight of the mallet plays a crucial role in determining the force it can deliver. Lighter mallets are ideal for tasks that demand precision and finesse, while heavier mallets are better suited for heavy-duty applications that require more power. Consider the nature of your task and the amount of impact required to select the appropriate weight.

The length of the mallet’s handle influences the leverage and control the user has during striking. Longer handles provide increased leverage for more powerful blows, while shorter handles offer greater precision and control for delicate tasks. Choose a handle length that complements the nature of your work and ensures a comfortable grip.

Consider the surface you will be striking. For tasks involving delicate or fragile materials, such as woodworking or metalworking with soft metals, a mallet with a softer striking surface, like rubber or rawhide, is essential to avoid damage. For tougher materials or heavy-duty tasks, a harder striking surface, such as metal or plastic, may be more suitable.

Ergonomics play a crucial role in the comfort and efficiency of using a mallet. Choose a mallet with a well-designed handle that provides a comfortable grip, reducing strain and fatigue during extended use. Some mallets feature textured or contoured handles, which enhance grip and prevent slippage, making them ideal for tasks requiring repetitive strikes.

In certain industries or applications, specialized mallets offer distinct advantages. For example, non-sparking mallets made from materials like nylon or copper are crucial in environments where sparks could pose safety risks. Similarly, dead blow mallets are invaluable in tasks that require reduced rebound and controlled impacts.

Ultimately, personal preference plays a role in selecting the right mallet. Factors such as balance, feel, and familiarity with a particular type of mallet can influence your decision. If possible, try out different mallets to see which one feels most comfortable and suits your working style.

Using a mallet properly is essential to achieve precise and effective results while ensuring safety during various tasks. Mastering the art of mallet usage involves a combination of proper technique, grip, and control. Here are some detailed guidelines for using a mallet effectively:

Begin by holding the mallet with your dominant hand, ensuring a firm and comfortable grip on the handle. Your non-dominant hand can either provide support on the handle or stabilize the workpiece. Maintain a stable stance with your feet shoulder-width apart, distributing your weight evenly to provide a solid base for striking.

Before striking, ensure that the mallet’s striking surface is properly aligned with the target area. For accurate and effective results, position the mallet perpendicular to the surface you are striking. Avoid tilting the mallet, as it can lead to off-center strikes and unintended outcomes.

When delivering strikes with a mallet, use controlled and consistent force. Avoid using excessive force, as it may cause damage to the workpiece or result in over-penetration. Instead, use measured strikes and gradually increase force as needed.

Depending on the task at hand, you may need to adjust the angle of the mallet. For tasks requiring more delicate impacts, use a glancing blow by slightly angling the mallet. For tasks requiring greater force, strike directly perpendicular to the target.

In some tasks, maintaining a steady pace and rhythm is essential. For instance, in woodworking, consistent and rhythmic mallet strikes during chiseling help achieve clean and precise cuts. Develop a comfortable and natural rhythm that complements the task’s requirements.

Complete each strike with a controlled follow-through to ensure the impact’s effectiveness. Avoid stopping abruptly after the strike, as it may reduce the force transfer and compromise the desired result.

Different materials require different striking techniques. For example, when working with delicate materials like wood or soft metals, use lighter and more controlled strikes to prevent damage. On the other hand, when dealing with harder materials, such as metal or stone, use more forceful strikes as needed.

Mastering mallet usage requires practice and precision. Regularly practice striking techniques on scrap materials to improve accuracy and control. As you gain experience, you’ll develop a better sense of the appropriate force and technique for various tasks.

Always prioritize safety when using a mallet. Wear appropriate safety gear, such as safety goggles and gloves, especially when working with materials that may produce flying debris. Keep your work area clear of clutter to prevent accidents or obstructions during striking.

Using mallets correctly is essential for achieving optimal results and maintaining safety in various tasks. To ensure a successful mallet operation, avoid the following common mistakes and pitfalls:

One of the most prevalent errors when using a mallet is applying excessive force. Using too much force can lead to unintended consequences, such as damaging the workpiece or causing over-penetration. Instead, focus on delivering measured and controlled strikes appropriate for the task at hand.

Using the wrong part of the mallet head or striking with an uneven surface can lead to inaccurate impacts and poor results. Ensure that the mallet’s striking surface is appropriate for the task, and position it correctly to avoid unintended glancing blows.

Avoid striking off-center, as it can cause the mallet to glance off the target or deliver an unbalanced impact. Aim for precision and accuracy in your strikes to achieve the desired results.

Using a soft mallet, such as rubber or rawhide, on hard surfaces may cause damage to the mallet head. Conversely, using a hard mallet on delicate materials can result in surface marring. Match the mallet’s hardness to the surface you are striking to prevent damage and achieve optimal outcomes.

Accidental hand or finger injuries can occur if they are positioned too close to the target area. Always keep your hands and fingers away from the striking zone to prevent accidents during mallet usage.

Avoid rushing through strikes or lacking control during mallet usage. Hasty and uncontrolled strikes can compromise the accuracy and effectiveness of the task. Instead, take your time, maintain focus, and exercise precise control over each strike.

Using mallets with signs of wear, damage, or loose parts can be hazardous. Regularly inspect your mallets and address any issues promptly to ensure safe and efficient use.

While mallets are versatile tools, they may not always be the best choice for every task. Avoid over-relying on mallets when other tools might be more appropriate or efficient.

Improper storage can lead to damage or wear on the mallet. Store your mallets in a dry and clean area to prevent moisture damage or exposure to extreme temperatures.

When working with mallets, wear appropriate safety gear, including safety goggles, gloves, and hearing protection, especially in noisy or hazardous environments.

Maintaining your mallets in good condition is crucial to ensure their longevity, efficiency, and safety during use. Follow these comprehensive maintenance and safety tips to keep your mallets in top shape and use them with confidence:

Perform regular inspections of your mallets to check for signs of wear, damage, or loose components. Pay attention to the handle, head, and joinery to ensure they are in excellent condition. Address any issues promptly to prevent further damage and maintain safe mallet operation.

Keep the mallet handle clean and free from debris or contaminants that may affect your grip and control. Use a soft cloth to wipe off dirt and dust, and consider applying a light coat of wood oil or wax to keep the handle smooth and protected.

If you are using wooden mallets, maintain the striking surface to prevent splintering and ensure a clean strike. Periodically sand or refinish the wooden head to keep it smooth and free from rough edges.

Inspect the joinery of your mallet, especially in traditional wooden mallets, to ensure a secure connection between the head and handle. If you notice any loosening or signs of weakness, reinforce the joinery or seek professional repairs.

Store your mallets in a dry and clean area to prevent moisture damage or exposure to extreme temperatures. Hanging your mallets or storing them on a flat surface can help maintain their shape and prevent warping.

Always prioritize safety when using mallets. Wear appropriate safety gear, such as safety goggles, gloves, and hearing protection, especially when working with materials that may produce flying debris or loud noises.

Select the right mallet for the task at hand to ensure efficiency and safety. Using the wrong mallet can lead to subpar results and potential hazards. Choose a mallet with the appropriate hardness and striking surface for your specific application.

Avoid using your mallet for purposes other than its intended use. Using a mallet as a hammer or for non-related tasks can lead to damage and compromise its functionality.

Exercise control when striking with a mallet to avoid overstriking, which can cause unnecessary stress on the tool and the workpiece. Apply measured force, and assess the impact before delivering subsequent strikes.

Treat your mallet with care, avoiding dropping it or subjecting it to excessive force. Even sturdy mallets can suffer damage from mishandling.

When not in use, store your mallets in a safe and designated area. Avoid placing heavy objects on top of them, as this can cause damage to the head or handle.

Mallets are versatile tools that find application across various industries, each benefiting from the unique characteristics of different mallet types. Let’s explore the diverse range of industries and tasks where mallets play a crucial role:

Woodworking tasks heavily rely on mallets for chiseling, mortising, and shaping wood. Wooden or rubber mallets are commonly used to deliver precise and controlled impacts without damaging delicate wood surfaces. Mallets allow woodworkers to achieve intricate details and perfect joints in their craftsmanship.

In the metalworking industry, mallets are invaluable for shaping metal sheets, riveting, and jewelry making. Rawhide or nylon mallets are preferred as they deliver controlled strikes without marring the metal surface. Metalworkers use mallets to manipulate metal into desired shapes and sizes, creating intricate pieces with accuracy.

Mallets are essential tools in construction for tasks such as driving nails, fitting joints, and aligning components. Rubber or plastic mallets are often used to prevent damage to materials during assembly. The controlled strikes of mallets make them ideal for various construction applications, ensuring secure and precise connections.

In the automotive industry, mallets assist in bodywork and repairs, where non-sparking copper mallets are valuable in sensitive environments. Automotive technicians use mallets to align parts, adjust panels, and reshape metal surfaces without damaging the vehicle’s finish.

Carpenters rely on mallets for assembling furniture, adjusting joints, and fine-tuning intricate woodworking projects. The versatility of mallets enables carpenters to work with precision and finesse, ensuring seamless constructions and well-fitted joinery.

For various DIY home repairs and installations, lightweight plastic mallets come in handy for quick and easy tasks. Mallets are used to assemble furniture, install fixtures, and perform small repairs around the house.

In leatherworking, mallets are employed to stamp patterns, set snaps, and rivet leather pieces. Rawhide mallets provide gentle yet firm impacts suitable for working with leather, ensuring clean and accurate impressions on the material.

In manufacturing industries, mallets are essential for tasks such as assembly, aligning components, and shaping materials. Mallets provide a controlled impact, making them indispensable in assembly line production and various manufacturing processes.

Mallets are used in masonry work for shaping bricks and stones, as well as for tapping them into place during construction. The weighted strikes of mallets help masons achieve precise positioning and even surfaces in their work.

In the jewelry-making industry, mallets are used to shape metal components and set gemstones. Delicate rawhide or nylon mallets are favored for their gentle impact, preventing damage to intricate jewelry pieces.

Blacksmiths use mallets to shape hot metal on the anvil during forging. Heavy-duty hammers with wooden or rawhide striking surfaces help blacksmiths shape metal with precision and control.

In conclusion, mallets are versatile and indispensable tools that find applications in numerous industries. From woodworking and metalworking to construction and automotive tasks, mallets deliver controlled impacts, ensuring precision and efficiency. Proper usage, maintenance, and safety measures are vital to maximize their effectiveness and longevity.

By following these guidelines, users can harness the full potential of mallets, achieving superior results in their respective fields and projects. Embrace the craftsmanship and adaptability of mallets, and let these simple yet powerful tools elevate your work to new heights.

A mallet typically has a larger, softer head compared to a hammer, which is usually smaller and made of metal. Mallets are commonly used for woodworking tasks, where they provide controlled impact without damaging delicate surfaces.

Mallets are versatile tools used in various applications, including woodworking, metalworking, leatherworking, and percussion instruments. They provide a non-marring striking force, making them ideal for tasks that require precision and control.

There are several types of mallets, such as wooden mallets, rubber mallets, rawhide mallets, and dead-blow mallets. Each type serves specific purposes, such as shaping materials, assembling furniture, or driving chisels.

To use a mallet, grip the handle firmly and strike the target surface with controlled force. Adjust the strength and angle of the strikes based on the task to avoid damage or achieve desired results.

Mallet heads are commonly made from materials like wood, rubber, plastic, rawhide, or metal. The handle can be made of wood, metal, or fiberglass, providing different levels of durability and weight.

Yes, mallets are commonly used in woodworking. They are invaluable for driving chisels, assembling joints, and tapping delicate parts into place without causing damage.

Select a mallet based on the task’s requirements. For delicate work, use a soft-headed mallet like rubber or rawhide. For heavier tasks, a wooden or metal mallet may be more suitable for delivering greater impact.

Mallets are available at hardware stores, specialty woodworking shops, and online retailers. Look for a reputable supplier that offers a variety of mallet types and sizes to suit your needs.

Yes, when using a mallet, wear appropriate safety gear such as eye protection and gloves. Ensure proper grip and control to avoid accidentally striking your hand or fingers. Use caution to prevent damage to the workpiece or injury to yourself.