Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Looking to elevate your lifting game? Learn the ins and outs of ‘How to use a spreader bar’ – the ultimate tool for smooth, secure, and efficient lifting operations. From attaching to loads like a pro to ensuring rock-solid safety measures, this guide has you covered. Discover the key components that make spreader bars tick and uncover the tricks to calculate load capacities like a lifting whiz.

Dive into the art of load balance and explore the versatility of spreader bars for various lifting setups. Curious about customization? We’ve got that covered too. Get ready to master the spreader bar game and tackle lifting tasks with confidence!

Key Summary: How to Use a Spreader Bar?

A spreader bar facilitates safe lifting. Select a bar with appropriate length and weight rating. Attach slings symmetrically to prevent tilting. Lift smoothly, avoiding sudden jerks. Prioritize worker training, adhere to load limits, and conduct regular equipment inspections.

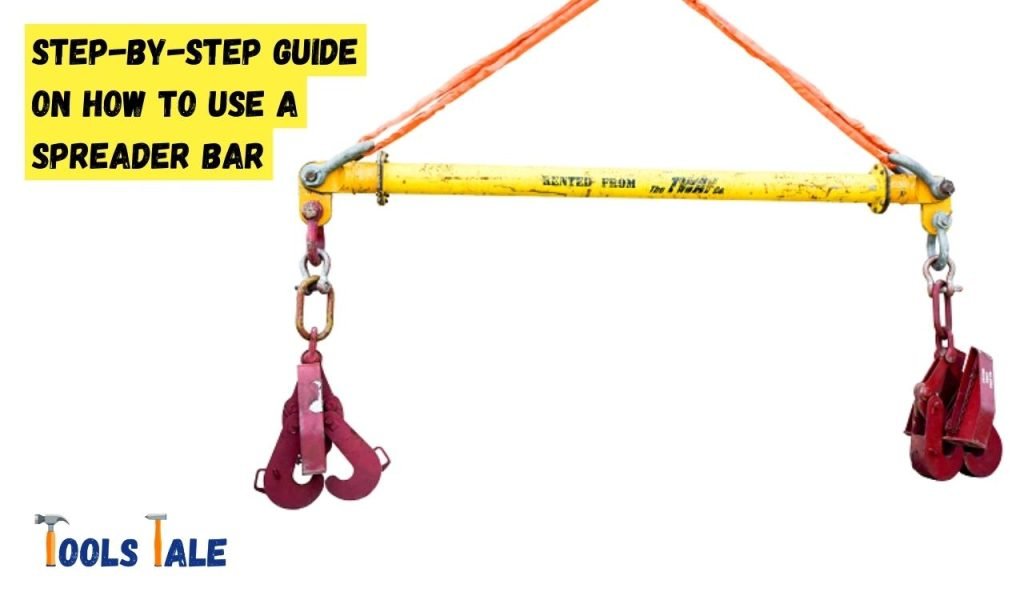

A spreader bar is a device used in various industries, including construction, lifting and rigging, and maritime applications. It consists of a rigid bar or beam that is designed to distribute the load evenly between multiple lifting points or to create a stable connection between two objects. Spreader bars are typically used to prevent damage to the lifted objects or to maintain proper balance during lifting operations.

In the context of lifting and rigging, a spreader bar is attached to the lifting cables or slings, creating additional lifting points and keeping the slings at a fixed distance from each other. This helps to prevent the slings from coming together and potentially damaging the lifted object, especially when it’s large or irregularly shaped.

Spreader bars are commonly used for lifting heavy loads such as steel beams, construction materials, and equipment. Maritime applications also utilize spreader bars in conjunction with cranes to load and unload cargo containers from ships. The spreader bar is used to secure the container’s corner castings, allowing the crane to lift and move the container without damaging it.

Spreader bars come in various sizes and designs to accommodate different lifting requirements and load capacities. They are an important tool for maintaining safety and efficiency in lifting operations, helping to evenly distribute loads and prevent accidents or damage.

When it comes to the intricate world of material handling and lifting, the spreader bar stands as a true game-changer. This ingenious device offers a wealth of advantages that extend beyond mere convenience, making it an indispensable asset in a range of industries. Let’s delve deeper into the multifaceted benefits that arise from harnessing the power of a spreader bar in various lifting operations.

At the core of the spreader bar’s benefits lies its remarkable ability to maintain load stability during lifting operations. By evenly distributing the weight across its length and attachment points, the bar counteracts the forces that often lead to load tilting or shifting. This enhanced stability translates into a safer working environment, protecting both personnel and valuable cargo from potential accidents and damage.

Using a spreader bar isn’t just about lifting efficiency; it’s also about safeguarding the integrity of the load being lifted. The even weight distribution that the bar facilitates minimizes the stress and strain experienced by the load.

This feature proves particularly crucial when dealing with delicate or fragile items that might be susceptible to deformation, breakage, or other forms of damage during the lifting process.

One of the standout advantages of the spreader bar is its adaptability to an array of load shapes and sizes. With multiple attachment points and a symmetric design, the bar can be tailored to accommodate the specific characteristics of various loads. This versatility negates the need for bespoke lifting solutions, thereby streamlining operations and optimizing resource allocation.

Lifting equipment, such as cranes and hoists, endures substantial stress during lifting operations. However, the spreader bar acts as a valuable ally in reducing this strain. By evenly distributing the load’s weight, the bar mitigates the concentration of force on specific points of the equipment. This reduction in strain not only enhances equipment longevity but also contributes to the overall efficiency and effectiveness of the lifting process.

Load mishandling or uneven lifting can lead to structural damage to both the load itself and the surrounding infrastructure. The spreader bar plays a pivotal role in preventing such damage by promoting uniform weight distribution and controlled lifting angles. This advantage is particularly vital in situations where the lifted load needs to be maneuvered through tight spaces or sensitive environments.

In the fast-paced world of industrial operations, time is often of the essence. Spreader bars offer a solution that not only enhances safety but also optimizes efficiency. With their ability to stabilize and distribute loads quickly and evenly, these bars contribute to faster and smoother lifting operations. This, in turn, translates into increased productivity and cost savings over the long run.

Using a spreader bar instills a sense of confidence in lifting operations. Knowing that the load is secure and stable reduces the potential for human error and unexpected incidents. This confidence extends to both operators and those overseeing the operation, fostering a work environment characterized by professionalism and a heightened commitment to safety.

When it comes to the operation of heavy lifting equipment like a spreader bar, safety takes center stage. The importance of adhering to strict safety precautions cannot be overstated.

By following these guidelines, not only do you protect yourself and your team, but you also ensure the smooth execution of lifting operations and the preservation of valuable cargo. Let’s delve into the comprehensive safety precautions that should be observed when working with a spreader bar.

Prior to commencing any lifting operation, a meticulous inspection of the spreader bar, lifting equipment, and load is imperative. Check for signs of wear, corrosion, or structural damage on the spreader bar. Inspect hooks, connectors, and other attachments for integrity and proper functionality. Any compromised component should be replaced immediately to avert potential hazards.

One of the cardinal safety rules is to stay within the spreader bar’s rated capacity. Overloading the bar can lead to structural failure, posing grave risks to personnel and property. Before lifting, determine the weight of the load and cross-reference it with the bar’s specified capacity. Erring on the side of caution is paramount to ensuring the safety of all involved.

Compatibility is key when it comes to lifting equipment and the spreader bar. Ensure that the lifting equipment you intend to use aligns with the design and load requirements of the spreader bar. Mismatched equipment can compromise the operation’s efficiency and safety. Always double-check that connections are secure and properly engaged before initiating the lift.

Proper attachment of the spreader bar to the load is non-negotiable. Verify that the attachment points on the load align with the spreader bar’s connection points. Hook or secure the attachments in a manner that ensures equal distribution of weight. An imbalanced attachment could lead to load tilting or instability during lifting.

Controlling lifting angles is essential for maintaining stability and preventing undue stress on the spreader bar and load. Ensure that the lifting angles are controlled and well within the safe operating limits. Abrupt or extreme changes in lifting angles can result in unexpected load shifts and potential accidents.

Throughout the lifting operation, maintain unwavering vigilance. Monitor the load for any signs of imbalance, shifting, or instability. If any irregularities are observed, pause the operation and assess the situation before proceeding. A watchful eye and a proactive approach can prevent accidents and mitigate risks effectively.

Effective communication and coordination among the team members involved in the lifting operation are essential. Establish clear lines of communication and designate roles and responsibilities. Ensure that everyone is aware of the operation’s plan, potential risks, and emergency procedures.

Despite meticulous planning, emergencies can arise unexpectedly. Be prepared by having well-defined emergency procedures in place. This includes knowing how to respond to equipment malfunctions, load instability, or any other unforeseen circumstances. Having a contingency plan and trained personnel ready to execute it can make all the difference in averting potential disasters.

Embarking on a lifting operation with a spreader bar requires a well-orchestrated approach that ensures both efficiency and safety. This comprehensive step-by-step guide will take you through the intricacies of using a spreader bar, providing you with the knowledge and confidence needed to execute successful lifting operations.

Begin by conducting a thorough inspection of the spreader bar, lifting equipment, and load. This meticulous assessment ensures that every component is in prime condition and ready for the lifting operation.

Check for signs of wear, corrosion, or any structural compromise on the spreader bar. Examine hooks, connectors, and attachments for integrity and proper functioning. Verify that the load is properly secured and ready for lifting.

Position the spreader bar over the load, ensuring that the attachment points on the bar align precisely with the designated lifting points on the load itself. This alignment is crucial for optimal load distribution and balance during the lifting process. Attach the hooks or connectors securely to the load, ensuring that they are properly engaged and capable of withstanding the lifting force.

With the spreader bar securely attached to the load, proceed to connect the lifting equipment. Fasten the lifting equipment, whether it’s a crane or a hoist, to the central attachment point on the spreader bar. Double-check that all connections are secure and that the lifting equipment is properly aligned with the spreader bar.

Initiate the lifting process gradually and smoothly. Engage the lifting equipment to apply tension to the spreader bar. As the load begins to lift, monitor its stability and balance closely. Ensure that the lifting angle remains controlled and that the load’s weight is evenly distributed across the spreader bar. Adjust the lifting angle if needed to prevent any potential tilting or uneven distribution of weight.

As the load is lifted off the ground, maintain vigilant observation. Keep a watchful eye on the spreader bar’s performance and the load’s stability throughout the ascent. Continuously assess the even distribution of weight and be prepared to address any signs of imbalance or unexpected movement promptly.

Once the load has reached its intended elevation, it’s time to initiate the descent. Lower the load gradually, maintaining controlled movement throughout. Avoid sudden shifts or jolts that could impact the load’s stability or cause safety hazards. Monitor the descent closely to ensure that the load remains steady and balanced.

After the lifting operation is completed, conduct a thorough post-lifting inspection. Examine the spreader bar, lifting equipment, and load to ensure that no damage has occurred during the operation. Look for any signs of wear, stress, or compromised integrity on the spreader bar’s components. Store the spreader bar properly, safeguarding it for future use.

Maintain meticulous records of the entire lifting operation. Record essential details such as load weights, equipment used, and any deviations from the planned procedure. These records serve as valuable references for future operations, contributing to the enhancement of lifting practices and safety measures.

The longevity and effective functionality of a spreader bar hinge on meticulous maintenance and care. Embracing a disciplined approach to these aspects not only safeguards the spreader bar’s structural integrity but also enhances the safety and efficiency of lifting operations. Delve into a detailed exploration of how to effectively maintain and care for your spreader bar:

Implement a systematic inspection routine before and after each use. Scrutinize every component, from hooks and connectors to attachment points. Look for signs of wear, damage, or corrosion. Vigilant inspection allows for the timely detection of potential issues that could compromise safety and performance.

After every lifting operation, dedicate time to clean the spreader bar meticulously. Remove dirt, debris, and other contaminants that could hinder its functionality. Use appropriate cleaning agents and methods to ensure that the bar remains in optimal condition.

Lubrication is pivotal in ensuring the smooth operation of a spreader bar. Apply suitable lubricants to moving parts, reducing friction and promoting seamless movement. Opt for lubricants that are compatible with the materials of the spreader bar to prevent degradation.

Where you store the spreader bar matters. Choose a clean, dry, and well-ventilated storage area to prevent moisture accumulation and corrosion. Shield the bar from extreme temperatures, direct sunlight, and harsh environmental conditions that can accelerate wear and tear.

A fundamental aspect of maintenance is adhering strictly to load capacity specifications. Exceeding the spreader bar’s rated capacity can lead to critical structural failures and jeopardize the safety of lifting operations. Maintain meticulous records of the loads lifted to ensure compliance with capacity limits.

Periodically schedule comprehensive inspections by qualified professionals. These experts can delve into aspects that might not be accessible during routine inspections, such as internal components and welds. Their expertise can unveil potential issues and guide necessary repairs or replacements.

As wear and tear are inevitable, promptly address any identified issues. Replace worn-out or compromised components to maintain the structural integrity of the spreader bar. Ignoring wear and tear could lead to safety hazards during lifting operations.

Empower operators with proper training in spreader bar usage, safety protocols, and emergency procedures. A well-trained team ensures that the spreader bar is used effectively, minimizing errors and accidents.

Keep meticulous records of maintenance activities, inspections, and repairs. These records serve as valuable references for tracking the spreader bar’s history, identifying patterns, and implementing continuous improvement strategies.

Adhere strictly to manufacturer guidelines, industry standards, and safety protocols. These guidelines are designed to ensure optimal performance and safety. Deviating from them can lead to compromised functionality and potential accidents.

Using a spreader bar effectively requires not only understanding proper procedures but also being aware of common mistakes to avoid. Recognizing and addressing these errors is pivotal in ensuring safe and efficient lifting operations. Here’s an in-depth examination of the common mistakes that can occur during spreader bar usage and how to steer clear of them:

Failing to adhere to load specifications is a grave mistake that can lead to catastrophic consequences. Overloading the spreader bar beyond its rated capacity compromises its structural integrity and increases the risk of accidents. Always verify the load’s weight and ensure it falls within the designated capacity limits of the spreader bar.

Improperly attaching the spreader bar to the load is a critical error that can result in load instability and imbalance. Ensure that the attachment points on the spreader bar align accurately with the lifting points on the load. Additionally, fasten hooks or connectors securely to prevent detachment during lifting.

Skipping pre- and post-operation inspections is a risky practice. Regular inspections serve as an essential safeguard by identifying potential issues before they escalate. Thoroughly examine the spreader bar, lifting equipment, and load for signs of wear, damage, or malfunction.

Communication breakdown among team members during lifting operations can lead to accidents. Ensure that there is clear and effective communication among all involved parties. This includes conveying roles, responsibilities, the operation plan, and potential risks to prevent misunderstandings.

Storing the spreader bar inadequately can accelerate wear and compromise its functionality. Avoid storing the bar in extreme temperatures, damp environments, or areas with corrosive substances. Proper storage safeguards the bar from unnecessary wear and extends its operational life.

Neglecting routine maintenance, including cleaning and lubrication, is a common pitfall. Regular maintenance is essential for preserving the spreader bar’s performance and structural integrity. Clean the bar after each use and apply suitable lubricants to moving parts to prevent friction.

Using a spreader bar without proper training can lead to errors and accidents. Ensure that operators are adequately trained in its usage, safety protocols, and emergency procedures. Proper training empowers operators to use the spreader bar effectively and confidently.

Disregarding manufacturer guidelines, industry standards, and safety protocols is a risky behavior. Always adhere to established guidelines for safe spreader bar usage. Deviating from these guidelines can compromise safety and lead to accidents.

Failing to maintain proper load balance during lifting operations can lead to instability and tilting. Ensure that the load is evenly distributed across the spreader bar to prevent unexpected shifts that could endanger personnel and equipment.

Rushing through the lifting operation without proper planning and execution is a significant mistake. Take the time to plan the operation thoroughly, communicate with team members, and execute each step with precision. Rushing increases the likelihood of errors and accidents.

In the world of heavy lifting, mastering the usage of a spreader bar requires a blend of precision, care, and vigilance. By delving into the intricacies of maintenance and care, and steering clear of common mistakes, you unlock the full potential of this essential lifting tool.

Rigorous inspections, strategic cleaning, meticulous adherence to load specifications, effective communication, and comprehensive training all contribute to safe and successful lifting operations.

Embracing these principles not only safeguards personnel and equipment but also paves the way for efficient and confident spreader bar usage. Remember, attention to detail and adherence to best practices elevate you from a user to a master of the spreader bar’s potential.

A spreader bar is a lifting tool designed to distribute the load’s weight evenly across its length. It prevents slippage, maintains load stability, and prevents damage to delicate or irregularly shaped loads during lifting operations.

To attach a spreader bar, position it over the load’s lifting points. Securely fasten hooks or connectors to the load’s designated lifting points, ensuring proper alignment for balanced lifting.

Prioritize safety by inspecting the bar and load, adhering to load capacity limits, ensuring proper balance, using suitable lifting equipment, and following industry guidelines to prevent accidents.

Yes, spreader bars can be used with various lifting equipment like cranes, hoists, or forklifts. Ensuring compatibility and using the appropriate rigging methods are essential for safe and effective usage.

A spreader bar consists of key components such as hooks, connectors, central attachment points, and crossbars. These components collaborate to evenly distribute the load’s weight and maintain stability.

Calculate the spreader bar’s load capacity by considering factors like its design, materials, and manufacturer specifications. Exceeding the rated capacity can lead to structural failure and hazardous situations.

Ensure load balance by aligning the spreader bar’s attachment points with the load’s lifting points. Proper rigging and maintaining an even weight distribution across the bar prevent tilting and instability during lifting.

Yes, various types of spreader bars cater to specific lifting scenarios. Adjustable spreader bars, lifting beams, and custom designs accommodate diverse load shapes, sizes, and industries.

Yes, spreader bars can be customized to fit specific lifting needs. Customization factors include load dimensions, weight, attachment points, and special requirements for safe and efficient lifting.

Proper operator training is essential. Training should cover spreader bar usage, safety protocols, load calculation, equipment compatibility, and emergency procedures to ensure safe and successful lifting operations.